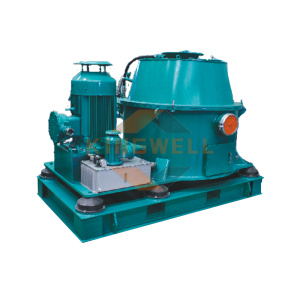

The vertical cuttings dryer ensures high efficiency of separation of drilling waste and minimizes the content of drill cuttings during oil and gas drilling. The main function of vertical cuttings dryer is to recover useful oil-based drilling fluid, reduce the oil content (OOC) of the cuttings, and reduce the total volume of cuttings that will be finally processed in the thermal desorption unit. The recovered oil-based drilling fluid will be returned to the solids control system. KWCD930 series dryer is mainly used for oil-based sludge, and also can be used for water-based sludge.

Vertical cuttings dryer uses centrifugal force to dry drill cuttings. Stainless steel screen rotate “wet” slurries and increase rotation speed to 900 RPM with G-force up to 420G. The liquid is passed through the holes of the screen basket, while the "Dry" slurries are extracted through angular flights into the cyclone, whose speed is slightly slower than the rotor. Tungsten carbide protects the blades from abrasive particles and ensures long service life. This helps maintain constant gap between the scrapers and screen, which is critical for proper operation.

Please contact us for detailed technical parameters

Technical Features of Vertical Cuttings Dryer

- Screen material - stainless steel, best protection against corrosion. The screen is made with high precision and dynamic balance to ensure better balance and easy replacement.

- The scrapers on the rotor have a hardness of HRC 65 with longer service life. Separate balancing on the scrapers and rotor is carried out for good performance and easy to repair

- Individual lubrication system with automatic low pressure alarm.

- The dryer motor and oil pump motor are interlocked, the dryer can only be started after the oil pump is started.

- Main bearings are spherical roller bearings manufactured by FAG Brand.

- Main electrical components from international brands: SIEMENS, Schneider, ABB or CHINT, etc.

Online consultation

Quick access to Technical Support and Detailed Quotations

CONTACT US

-

This email address is being protected from spambots. You need JavaScript enabled to view it. -

+86 315 2031752