VIST is especially designed for the drilling cuttings drying with shale shaker in oil and gas drilling, through the last shaker screen to effectively dry the discharged cuttings, and achieve the goal of reducing waste and reusing drilling fluids.

This system is a completely pneumatic system, without any electrical elements, and can be widely used for OBM, SBM and WBM for onshore and offshore drilling.

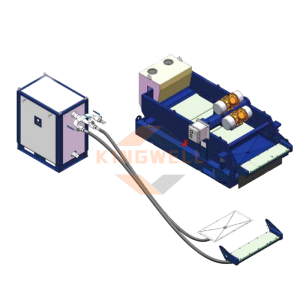

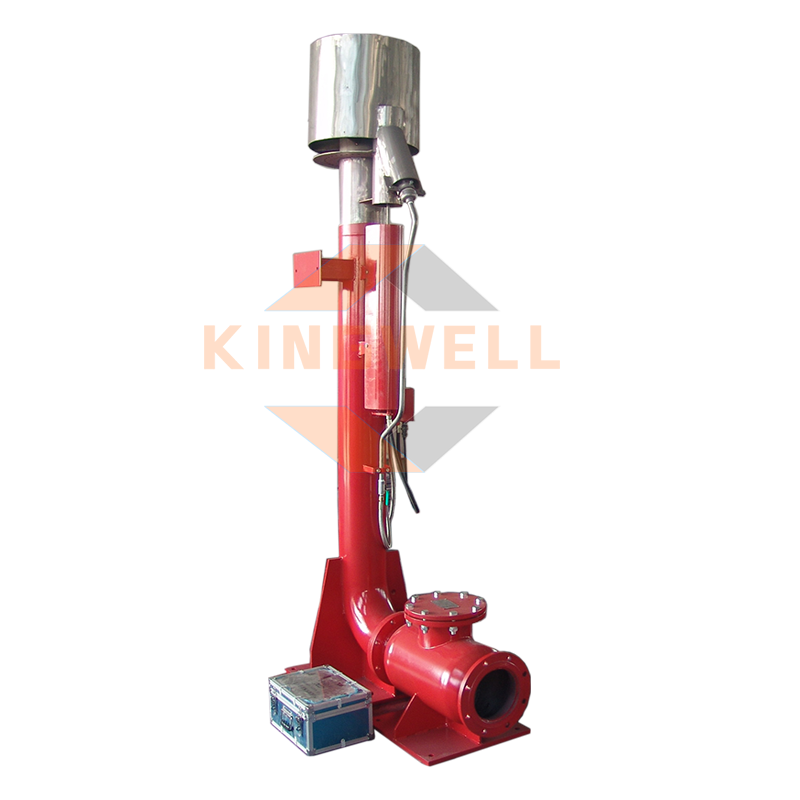

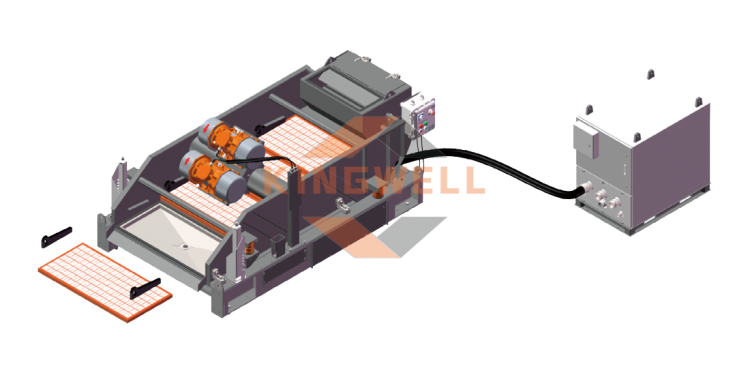

VIST (installed below the last screen)

Below is photo of a VIST, with pallets installed below the last screen

| Model | KWVS |

|---|---|

| Operating pressure, MPa | 0.7 –1.0Mpa(100-150PSI) |

| Air flow rate, m3/min | 7.9 m3/min. (160CFM) |

| Number of simultaneously operating shakers, pcs | 1-3SET |

| Drilling mud type | OBM,SBM,WBM |

| Reduction of mud losses on cuttings, % Up to | 30%-50% |

| Drilling mud volume per 1 shale shaker | About 2000-3000 l/day (additional volume using) |

| Drilling mud temperature | 0 +85°C |

| Inlet | 2 inch, 3 pcs |

| Outlet | 2 inch, 1 pc |

| Air inlet | 1 inch, 1 pc |

| Dimension,mm | 1058x730x1068mm (350KG) |

| Remarks | Pneumatic control, no requirement for electrical energy. Suction and discharge times can be adjusted. |

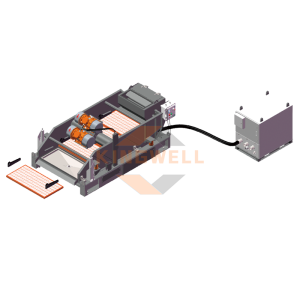

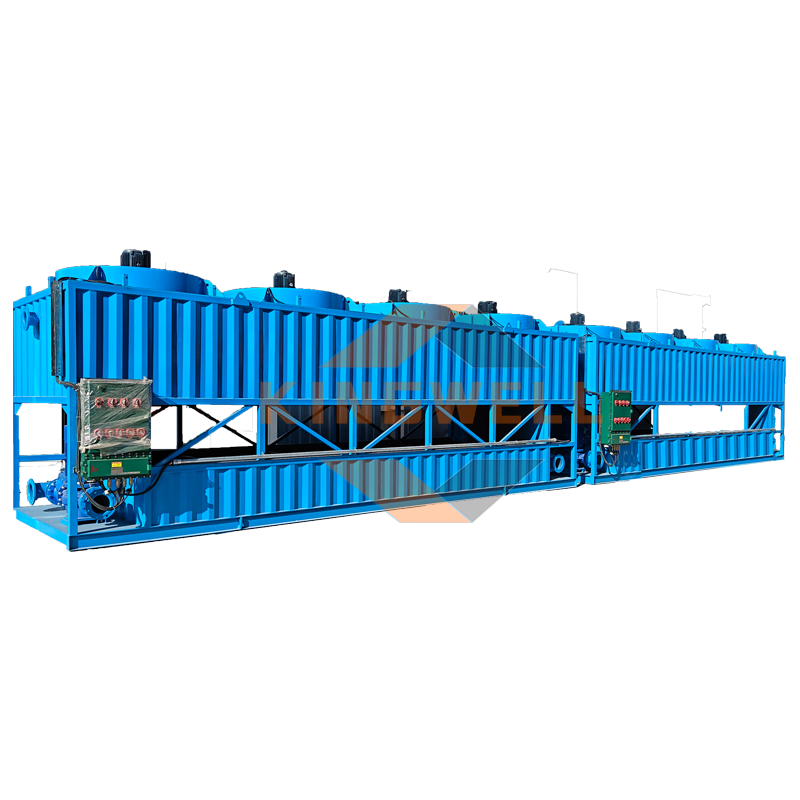

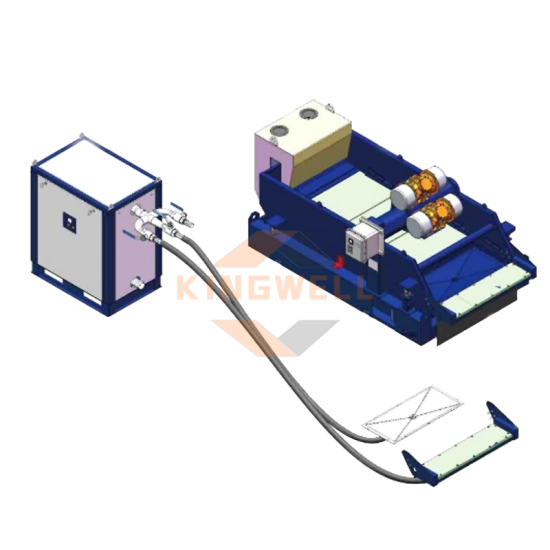

VIST (be installed with an additional screen)

Below is VIST photo, which pallets installed under the last piece of screen.

| Model | KWVS |

|---|---|

| Operating pressure, MPa | 0.7 –1.0Mpa(100-150PSI) |

| Air flow rate, m3/min | 7.9 m3/min. (160CFM) |

| Number of simultaneously operating shakers, pcs | 1-3SET |

| Drilling mud type | OBM,SBM,WBM |

| Reduction of mud losses on cuttings, % Up to | 30%-50% |

| Drilling mud volume per 1 shale shaker | About 2000-3000 l/day (additional volume using) |

| Drilling mud temperature | 0 +85°C |

| Inlet | 2 inch, 3 pcs |

| Outlet | 2 inch, 1 pc |

| Air inlet | 1 inch, 1 pc |

| Dimension,mm | 1058x730x1068mm (350KG) |

| Remarks | Pneumatic control, no requirement for electrical energy. Suction and discharge times can be adjusted. |

Technical Features of VIST

- Widely used for OBM, SBM and WBM.

- To replace the drying shaker without additional consumption of screens. Less footprint and easy installation without welding.

- Reduce waste by 30% to 50%. A finer screen can be used to improve solids control.

- Less cost for transporting drill cuttings.

- No need for electric power, suitable for use in hazardous areas.

- Suction and discharge times are adjusted according to drilling conditions.

Online consultation

Quick access to Technical Support and Detailed Quotations

Please fill out the form below so that we can quickly answer your questions and provide you with our high-quality technical support. You can also contact us through email, and our team will provide you with excellent service.

CONTACT US

-

This email address is being protected from spambots. You need JavaScript enabled to view it. -

+86 315 2031752