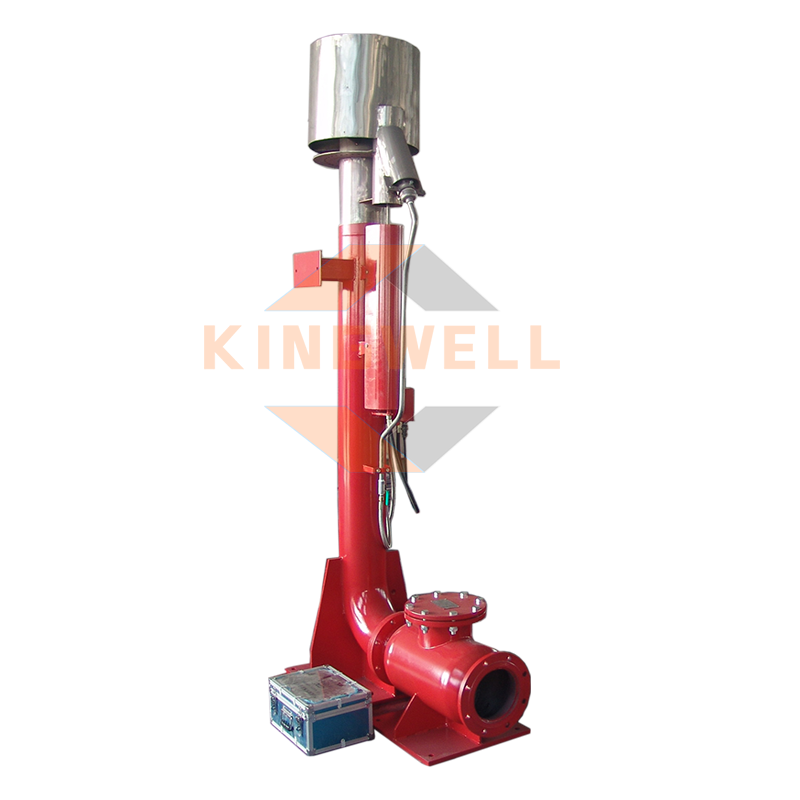

Centrifugal Degasser

PRODUCTS

- Oil Drilling rig & Equipment

- Solids Control

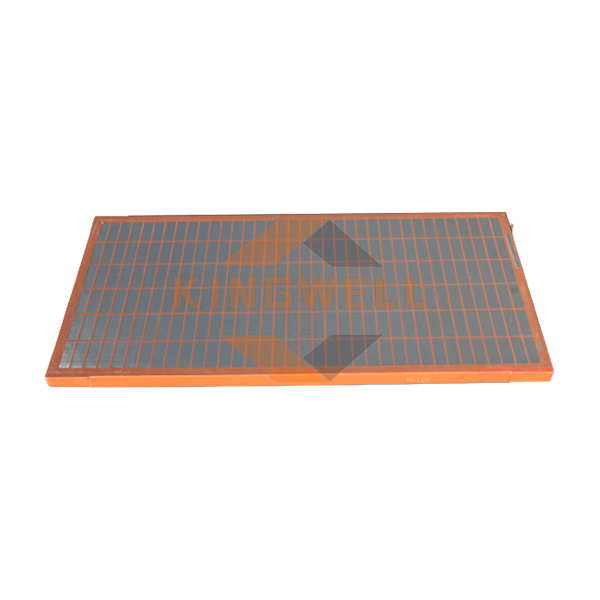

- Shale Shaker

- API Shaker screens

- Decanter centrifuge

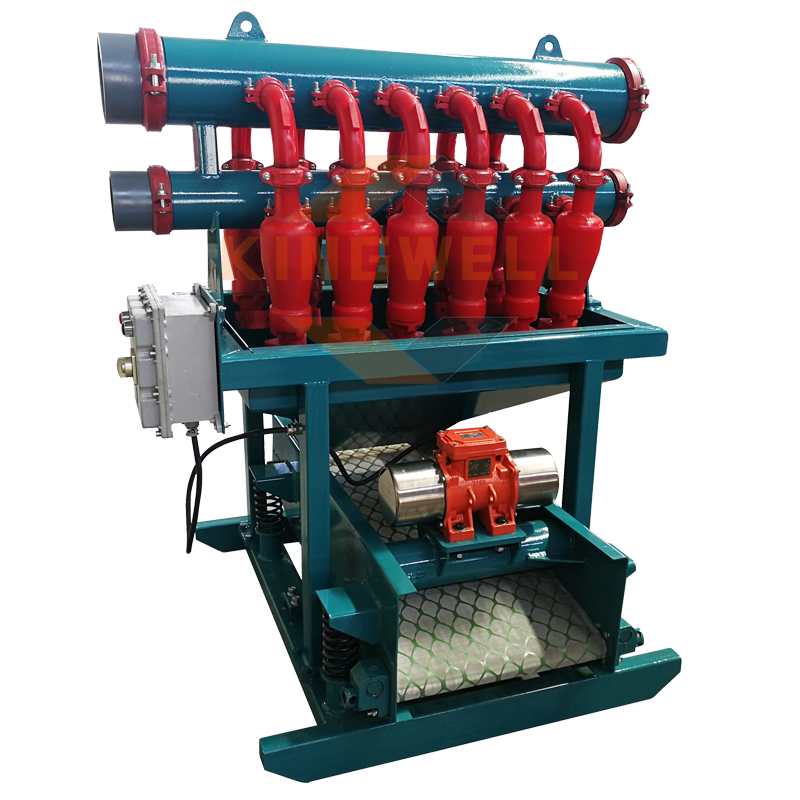

- Mud Cleaner

- Desander

- Desilter

- Centrifugal Degasser

- Vacuum Degasser

- Mud Agitator

- Mud Hopper

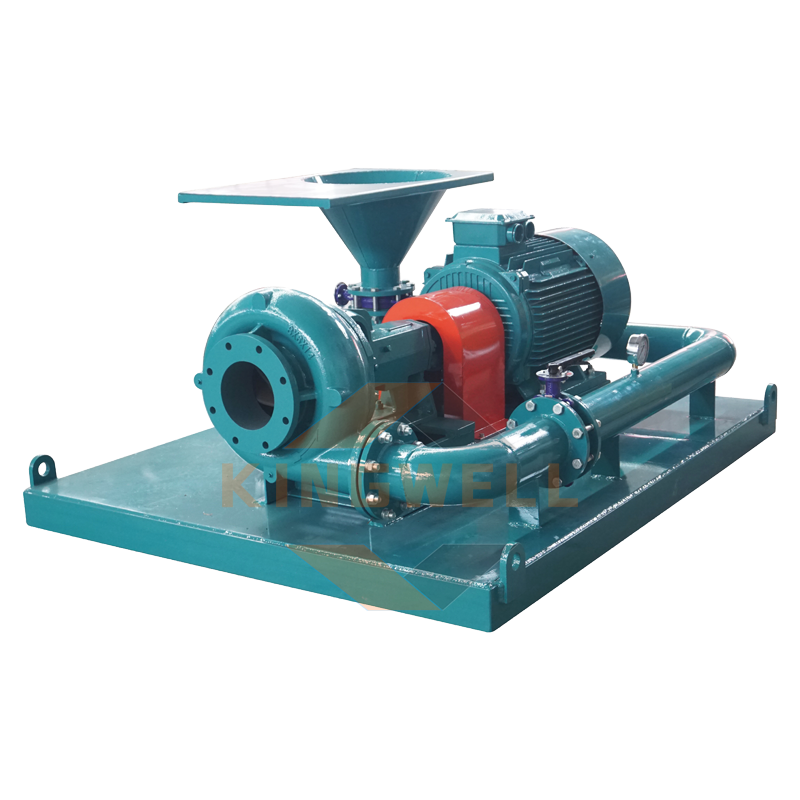

- Jet Mud Mixer

- Centrifugal Pump

- Screw Conveyer

- Screw Pump

- Submersible Slurry Pump

- Flare Ignition Device

- Mud Gun

- Mud Solids Control System

- Mud Cooling System

- Mud Tanks

- Drilling Waste Management

- Separation Technology

- Packaged Mud Recycling Systems

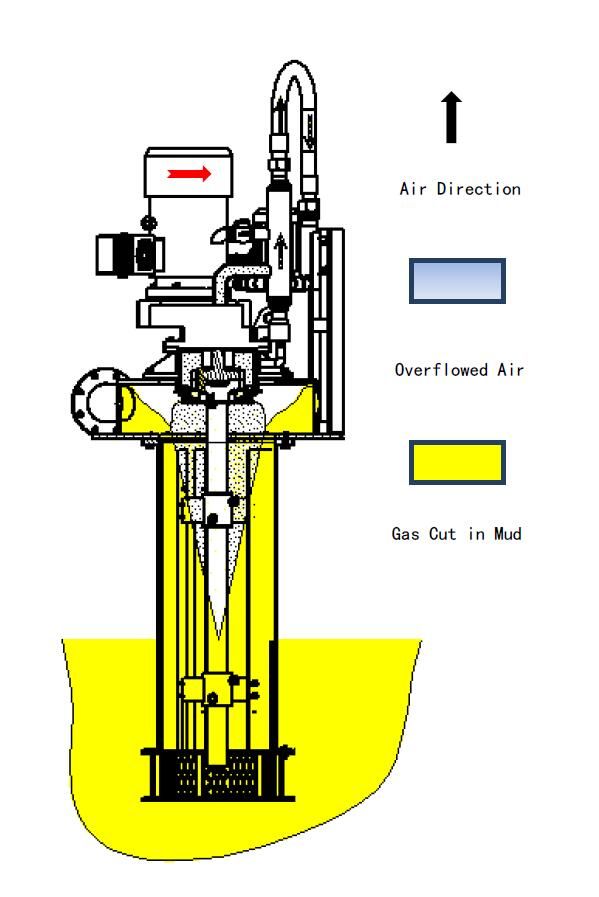

Centrifugal Degasser is used to remove the gas phase from the drilling fluid. Centrifugal Degasser is usually installed directly after the shaker, is widely used in mud systems and plays an important role in restoring the density and stabilizing the viscosity of drilling fluid. And it can also be used as a high-power mixer for preparing drilling fluid. It has high performance, high degassing speed, ergonomics, low energy consumption, ease of operation and maintenance.

This is a new type of degasser developed by our company based on the integration of various types of degassers in the world. Comparing with KINGWELL vacuum degasser, centrifugal degasser has smaller footprint and low power consumption, and can also achieve the following functions:

- Restoring the gravity of drilling fluid when drilling oil and gas wells.

- Separation of gas phase from the drilling fluid and their direction into the gas-air line

- Use as a second stage after the mud gas separator (in the case of drilling method with equilibrium and unbalanced pressure in the well)

Technical parameters of Centrifugal Degasser

| Model | KWLCQ300 |

|---|---|

| Liquid Inlet Size, inches | 20 |

| Liquid Outlet Size, inches | 6 |

| Gas Outlet Size, inches | 2 |

| Max Liquid Throughput, m3/h | 300 |

| Max Gas Removed, m3/h | 30 |

| Main motor, kW | 22 |

| Fan Motor, kW | 1.1 |

| Gearbox Ratio 1:5 | 1:5 |

| Weight, kg | 1400 |

| Dimensions, mm | 1150×1054×3110 |

Working principle of Centrifugal Degasser

Online consultation

Quick access to Technical Support and Detailed Quotations

CONTACT US

-

This email address is being protected from spambots. You need JavaScript enabled to view it. -

+86 315 2031752