BOP Control Systems

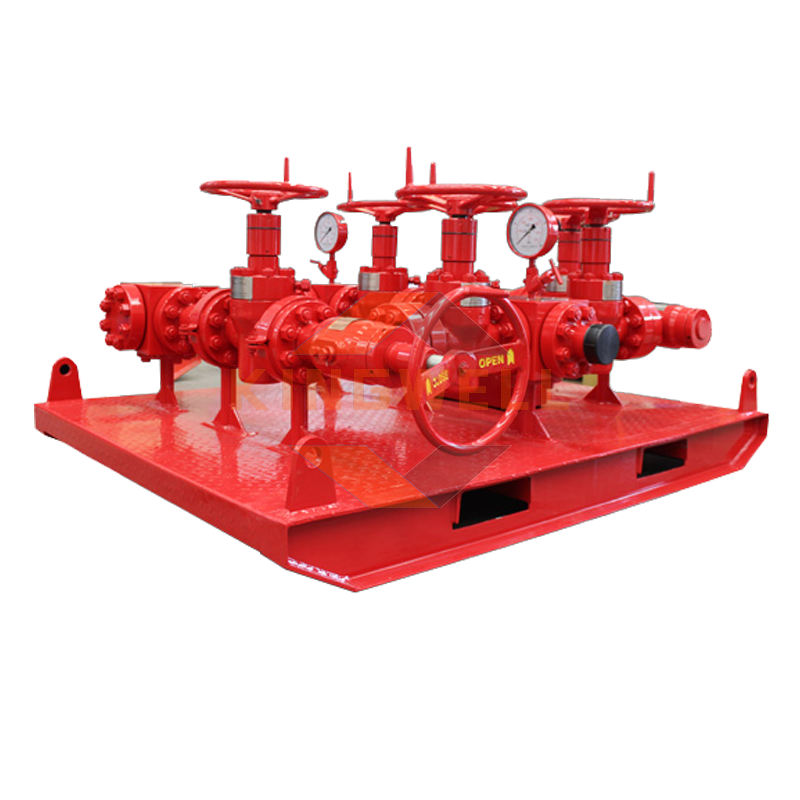

The BOP control system is designed for operational remote control of BOP and valves of the throttling and killing manifold, in order to seal the wellhead, with the drill pipe string located in it or in their absence. A BOP control system is an essential equipment to prevent a blowout during drilling or well workover in the oil and gas industry.

The BOP control system consists of two mutually interlocked consoles: the main one, which includes a hydraulic drive station and a pneumatic-hydraulic accumulator unit (PHA), and an auxiliary console. The main console in the BOP control system is mounted together with pneumatic hydraulic accumulators, which, in accordance with safety rules, must be located outside the base of the drilling rig no closer than 10 m from the wellhead. The auxiliary control panel allows you to control preventers and valves from the driller's workplace.

Technical parameters for BOP control system

|

Type |

Controlled objects QTY |

Accumulator sets |

Effective volume of oil reservoir L |

Flow rate of pump |

Power, KW. |

Working pressure, Mpa |

||

|

Total Vol.L |

Nom.available Vol. L |

Elec. pump, L/min. |

Punematic pump, ml/stroke |

|||||

|

FKQ240-3 |

3 |

40X6 |

120 |

560 |

20 |

165 |

11 |

21 |

|

FKQ320-4 |

4 |

40X8 |

160 |

650 |

20 |

165 |

11 |

21 |

|

FKQ320-5 |

5 |

40X8 |

160 |

650 |

20 |

165 |

11 |

21 |

|

FKQ400-5 |

5 |

40X10 |

200 |

900 |

30 |

165 |

15 |

21 |

|

FKQ400-6 |

6 |

40X10 |

200 |

900 |

30 |

165 |

15 |

21 |

|

FKQ480-5 |

5 |

40X12 |

240 |

1000 |

30 |

165 |

15 |

21 |

|

FKQ480-6 |

6 |

40X12 |

240 |

1000 |

30 |

165 |

15 |

21 |

|

FKQ640-6 |

6 |

40X16 |

320 |

1300 |

40 |

165X2 |

18.5 |

21 |

|

FKQ640-7 |

7 |

40X20 |

400 |

1300 |

40 |

165X2 |

18.5 |

21 |

|

FKQ800-7 |

7 |

40X20 |

400 |

1500 |

40 |

165X2 |

18.5 |

21 |

|

FKQ800-8 |

8 |

40X20 |

400 |

1600 |

40 |

165X2 |

18.5 |

21 |

|

FKQ960-6 |

6 |

80X12 |

480 |

1800 |

40 |

165X3 |

18.5 |

21 |

|

FKQ960-7 |

7 |

80X12 |

480 |

1800 |

40 |

165X3 |

18.5 |

21 |

|

FKQ960-8 |

8 |

80X12 |

480 |

1800 |

40 |

165X3 |

18.5 |

21 |

|

FKQ1280-8 |

8 |

80X16 |

640 |

2000 |

40X2 |

165X3 |

18.5X2 |

21 |

|

FKQ1280-9 |

9 |

80X16 |

640 |

2000 |

40X2 |

165X3 |

18.5X2 |

21 |

|

FKQ1280-10 |

10 |

80X16 |

640 |

2000 |

40X2 |

165X3 |

18.5X2 |

21 |

|

FKDQ480-5 |

5 |

40X12 |

240 |

1000 |

30 |

165 |

15 |

21 |

|

FKDQ480-6 |

6 |

40X12 |

240 |

1000 |

30 |

165 |

15 |

21 |

|

FKDQ640-6 |

6 |

40X16 |

320 |

1300 |

40 |

165X2 |

18.5 |

21 |

|

FKDQ640-7 |

7 |

40X16 |

320 |

1300 |

40 |

165X2 |

18.5 |

21 |

|

FKDQ800-7 |

7 |

40X20 |

400 |

1500 |

40 |

165X2 |

18.5 |

21 |

|

FKDQ800-8 |

8 |

40X20 |

400 |

1600 |

40 |

165X2 |

18.5 |

21 |

|

FKDQ960-7 |

7 |

80X12 |

480 |

1800 |

40 |

165X3 |

18.5 |

21 |

|

FKDQ960-8 |

8 |

80X12 |

480 |

1800 |

40 |

165X3 |

18.5 |

21 |

|

FKDQ1280-8 |

8 |

80X16 |

640 |

2000 |

40X2 |

165X3 |

18.5X2 |

21 |

|

FKDQ1280-9 |

9 |

80X16 |

640 |

2000 |

40X2 |

165X3 |

18.5X2 |

21 |

|

FKDQ1280-10 |

10 |

80X16 |

640 |

2000 |

40X2 |

165X3 |

18.5X2 |

21 |

|

FKD640-6 |

6 |

40X16 |

320 |

1300 |

40 |

165X2 |

18.5 |

21 |

|

FKD800-7 |

7 |

40X20 |

400 |

1500 |

40 |

165X2 |

18.5 |

21 |

|

FKD960-8 |

8 |

80X12 |

480 |

1800 |

40 |

165X3 |

18.5 |

21 |

Technical Features of BOP Control System

- Full switch control with sequence parameters and indicators.

- Alarm systems to alert the operator to potential problems and the need to stop drilling operations to prevent a possible uncontrolled situation in the well.

- The components have been field-tested for decades to ensure reliability, maximum service life, and minimal downtime.

- It works with the control equipment of most PLC manufacturers to be compatible with your rig's electronics.

- It can be designed and manufactured to any specification, including ATEX, all European directives, GOST, NORSOK, DNV, ABS and specifications of all major oil companies.

Type Illustration of BOP Control System:

-

FKQ Series BOP Control System:

Pneumatic Controlled

-

FKDQ Series BOP Control System:

Electric-Pneumatic Controlled, PLC based control, Driller ' s Panel (touch screen or electric button), Wireless remote control function can be selected

-

FKD Series BOP Control System:

Electric Controlled, Rongsheng patent products, Electromagnet driven, PLC based control, Driller ' s Panel (touch screen or electric button), Wireless remote control function can be selected

Note:

Q: The FKQ series uses hose bundle to connect the driller ' s panel with the remote control panel,the driller operating element is pneumatic rotary valves, remote control panel uses cylinder to drive the 4-way 3-position valve,this series can choose pneumatic-manual or pneumatic motor driven pressure regulating valves.

DQ: The FKDQ series uses signal cableto connect the driller ' s panel with the remote control panel, the driller operating element is touch screen or electric button, remote control panel uses cylinder to drive the 4-way 3-position valve, with pneumatic motor driven pressure regulating valves.

D: The FKD series uses signal cableto connect the driller ' s panel with the remote control panel, the driller operating element is touch screen or electric button, remote control panel uses electromagnet to drive the 4-way 3-position valve, with electromotor driven pressure regulating valves.

If the customer want to order an API Spec. 16D control system, and you need to mark the API monogram on it, you need to obtain a form named “configuration and parameters of the bop stacks for order an API Spec. 16D control system (land and surface)” from Rongsheng sales department. After filling in the detailed technical parameters, the Rongsheng technical department will carry out the selection calculation.

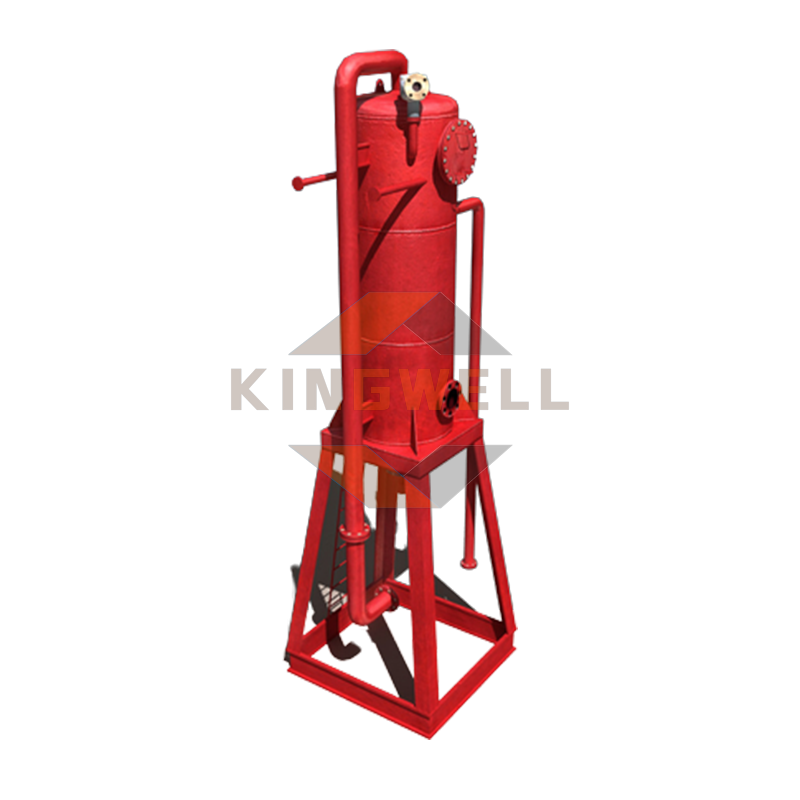

The optional device:

All series can choose BOP heating units, to heating bop in extremely cold environment, enable the bop to function normally (the BOP should have heating function).

FKDQ & FKD series can choose wireless remote control function.

Online consultation

Quick access to Technical Support and Detailed Quotations

CONTACT US

-

This email address is being protected from spambots. You need JavaScript enabled to view it. -

+86 315 2031752