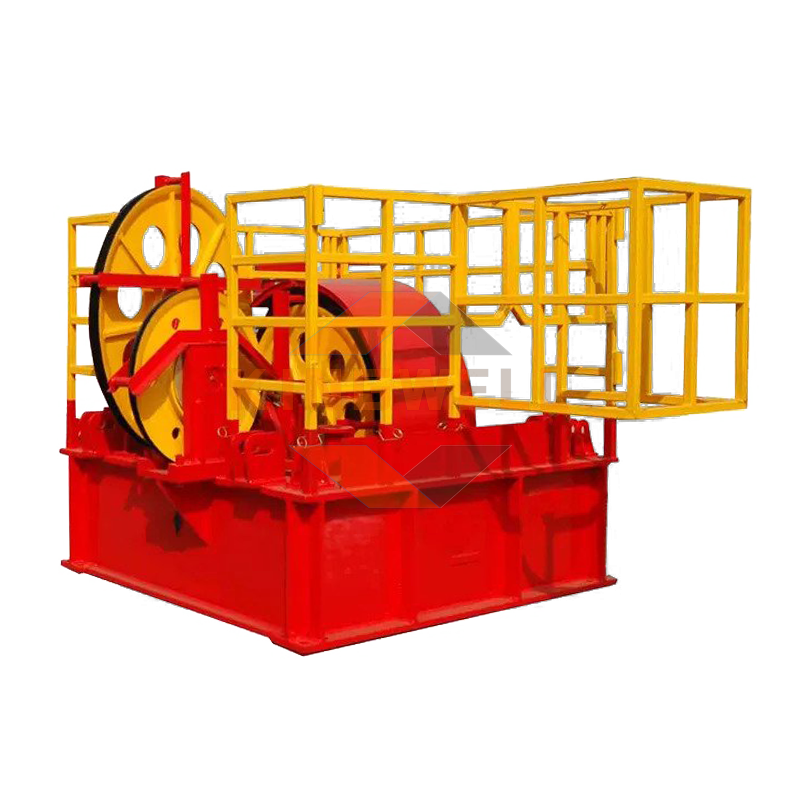

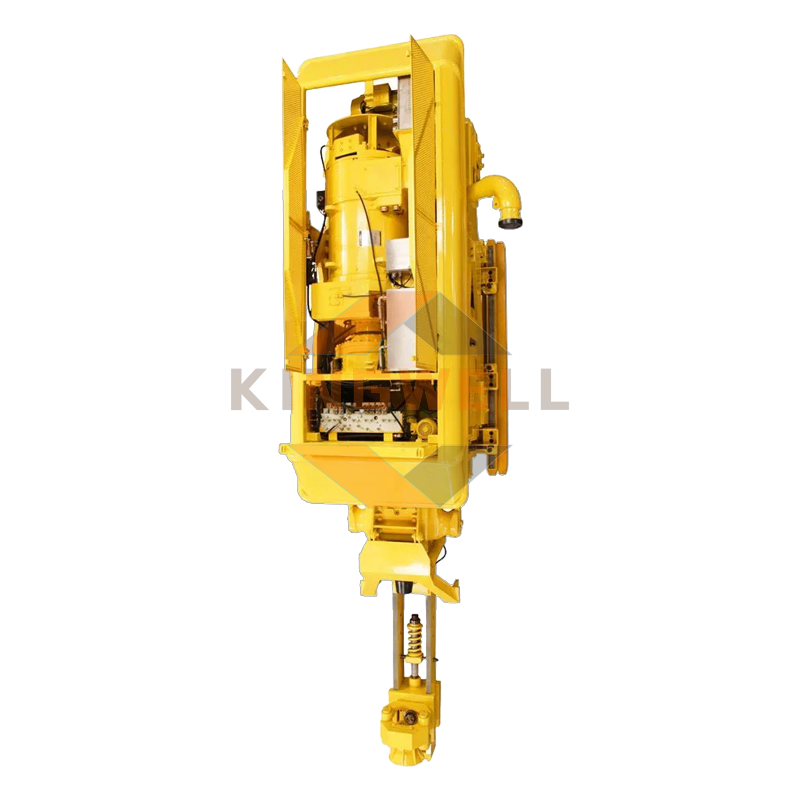

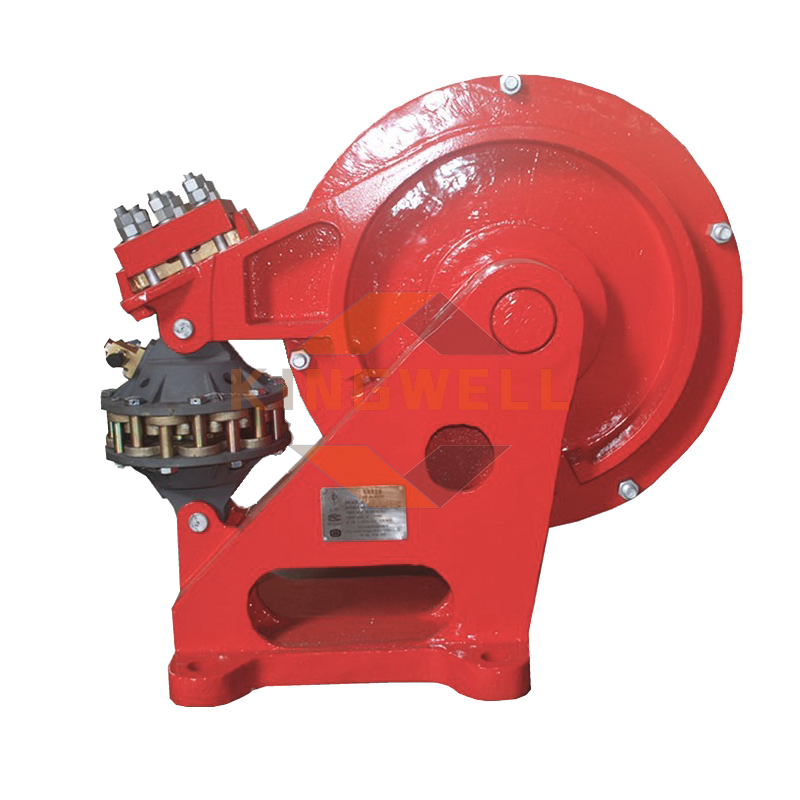

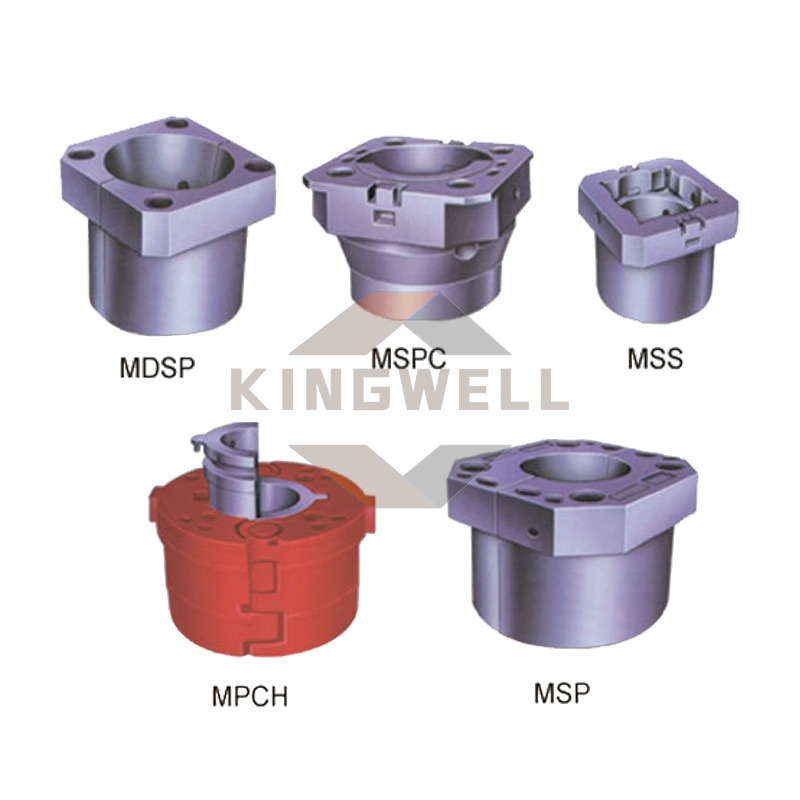

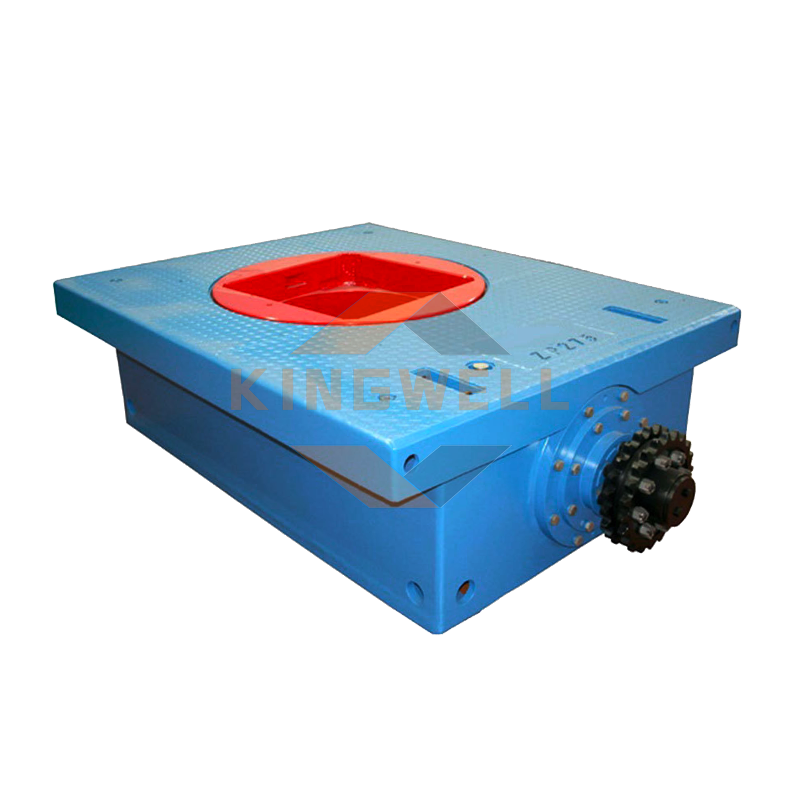

Rotary Table

The drilling rotary table is one of the most important devices for the oil and gas drilling rig, designed to rotate the drilling tool and support the weight of the drill pipe and casing string on the slips or on the elevator during the oil and gas drilling. And complete with PKR wedges for gripping and releasing drill strings during tripping and running of the casing.

Technical Parameters of Rotary Table

| Model | ZP135 | ZP175 | ZP205 | ZP275 | ZP375 | ZP495 |

| Through hole dia. (mm/in) | 315(12 1/4) | 444.5(17 1/2) | 520.7(20 1/2) | 698.5(27 1/2) | 952.5(37 1/2) | 1257.3(49 1/2) |

| Max. static load(lbf) | 303492 | 303492 | 708148 | 1011640 | 1315132 | 1618560 |

| Rated torque(lbf.ft) | 8850 | 10325 | 16595 | 20282 | 23867 | 27288 |

| Distance between rotary table center and chanin wheel internal teeth center(ft) | 3.66 | 3.66 | 4.43 | 4.43 | 4.43 | 5.42 |

| Max. speed(r/min) | 300 | 300 | 300 | 300 | 300 | 300 |

| Gear ratio(i) | 3.5 | 3.58 | 3.62 | 3.67 | 3.56 | 3.93 |

| Center height(in) | 6.29 | 10.62 | 12.51 | 12.99 | 12.99 | 12.99 |

| Overall dimension(ft) | 5.59x3.51x1.24 | 6.24x4.19x1.88 | 7.57x4.83x2.19 | 7.92x5.51x2.25 | 8.09x5.93x2.35 | 9.65x7.17x2.67 |

| Weight(lbs) | 3007.1 | 8238.66 | 9208.69 | 14931.89 | 17694.28 | 25630.91 |

Technical Features for Drilling Rotary Table

- The shell of rotary table is cast steel and welded steel plate structure, and the basement is cast steel.

- The transmission gear of rotary table is the arc bevel gear with hard tooth surface, which has high strength, smooth transmission, large transmission torque and long service life.

- The transmission shaft is made of alloy forgings. The overall mechanical performance is good, suitable for large torque work. The shaft end can be installed with sprocket and flange, which can adapt to the requirements of various transmission modes.

- The main rotary table bushing is made of alloy cast steel and tempered with high strength and reliable performance.

- Rotary Table is designed and manufactured in accordance with API Spec.7K specification.

- A reliable seal protects it from drilling mud, while increasing the service life of the gear pair and the main table support.

Online consultation

Quick access to Technical Support and Detailed Quotations

Please fill out the form below so that we can quickly answer your questions and provide you with our high-quality technical support. You can also contact us through email, and our team will provide you with excellent service.

CONTACT US

-

This email address is being protected from spambots. You need JavaScript enabled to view it. -

+86 315 2031752