Screw Pump

PRODUCTS

- Oil Drilling rig & Equipment

- Solids Control

- Shale Shaker

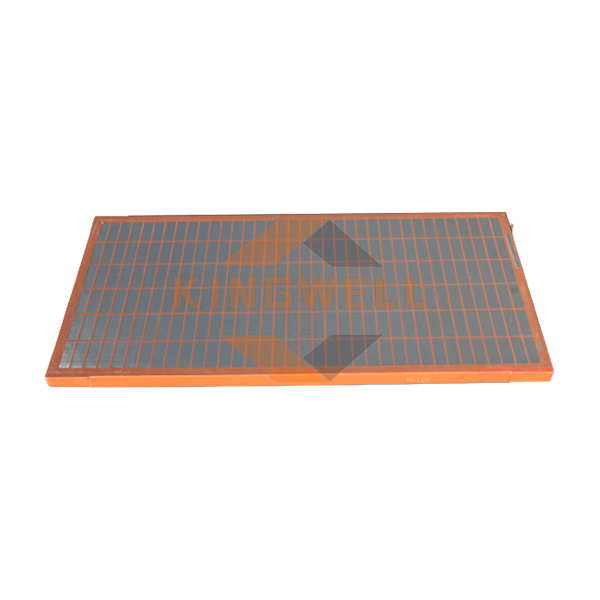

- API Shaker screens

- Decanter centrifuge

- Mud Cleaner

- Desander

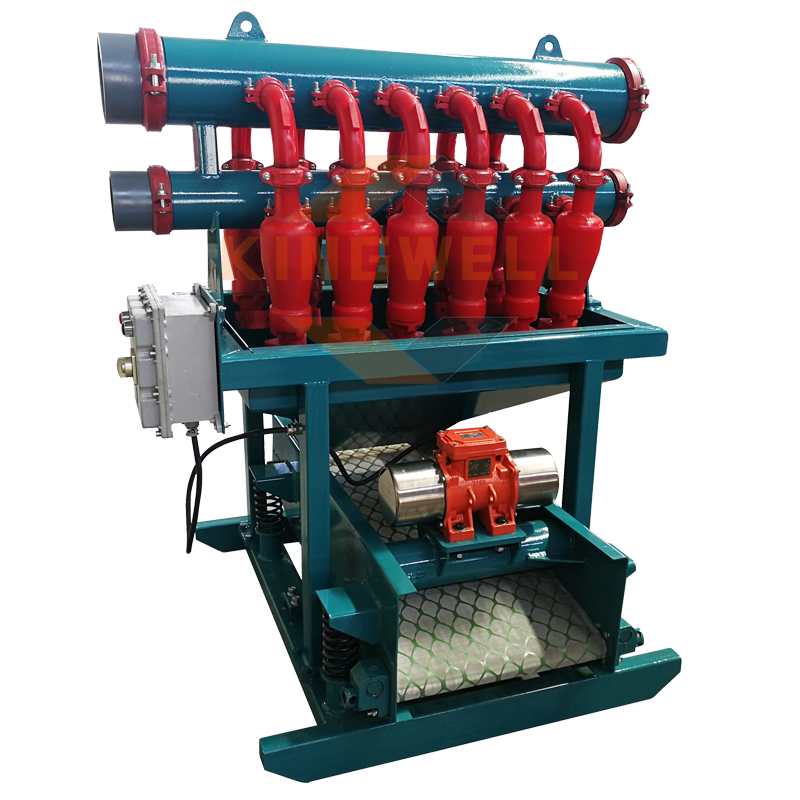

- Desilter

- Centrifugal Degasser

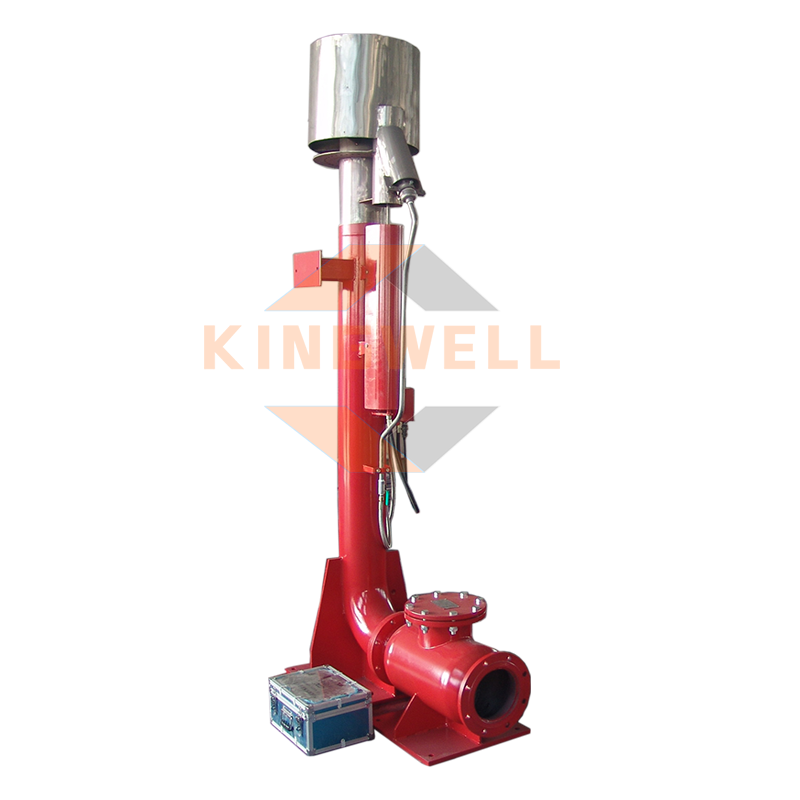

- Vacuum Degasser

- Mud Agitator

- Mud Hopper

- Jet Mud Mixer

- Centrifugal Pump

- Screw Conveyer

- Screw Pump

- Submersible Slurry Pump

- Flare Ignition Device

- Mud Gun

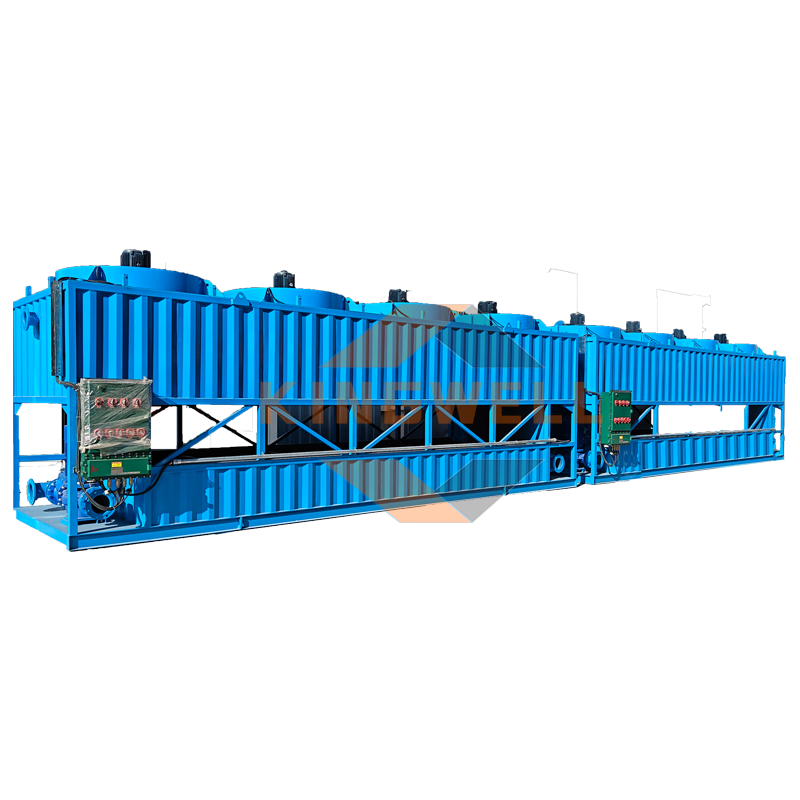

- Mud Solids Control System

- Mud Cooling System

- Mud Tanks

- Drilling Waste Management

- Separation Technology

- Packaged Mud Recycling Systems

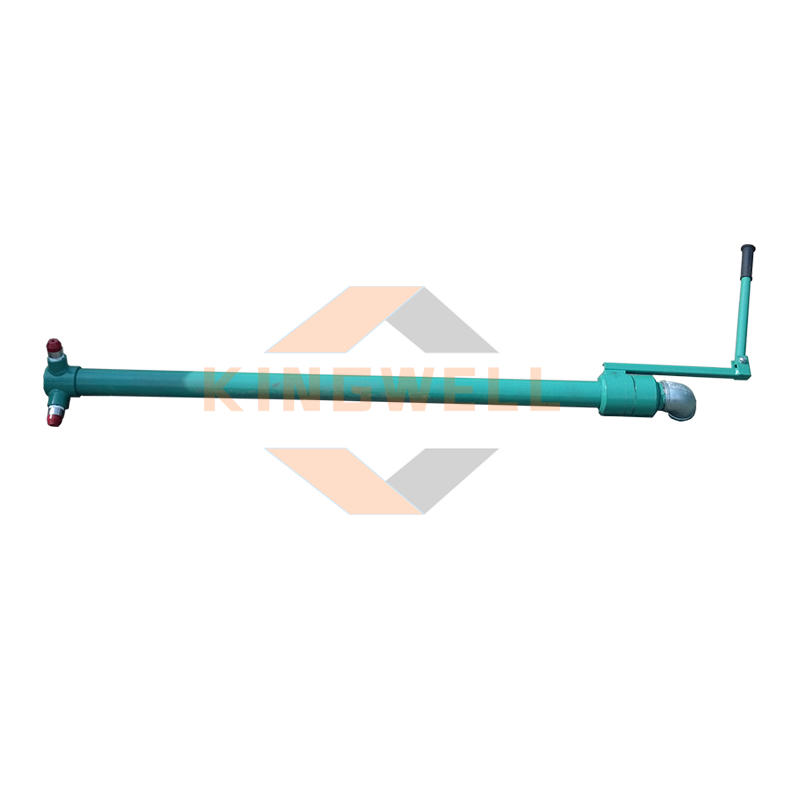

Screw pump is a positive displacement pump that uses one or more screws to move liquid or solid material along the axis of the screw. The screw pump has many special technical advantages over other types of pumps, and the screw pump has a very wide range of applications. The screw pump can pump liquid continuously without pulses and with stable discharge pressure.

The KWG series screw pump is a single screw pump, which is an ideal machine for feeding decanter centrifuge without shearing or agitating the drilling mud. The fluids flow along with the rotor, inner flow speed is slow, capacity remains, pressure is steady, so it will not generate vortex and agitating. The screw pump can be carried out through frequency converter or mechanical gearbox.

The KWG series screw pump has NBR stator and stainless steel rotor to ensure reliable operation. Compared with other pumps, the screw pump is difficult to cause turbulence. This is very helpful in maintaining the pump's performance. It is not sensitive to viscosity, so it can carry high viscosity material.

Technical Specifications of Screw Pump(Fixed Speed)

| Model | Flow, m3/h | Lift, m | Motor, kW | Speed, RPM | Inlet | Outlet | Weight, kg | Dimensions LxWxH, mm |

|---|---|---|---|---|---|---|---|---|

| KWG10-040 | 10 | 0.3 | 4 | 244 | DN80 | DN80 | 258 | 2165x380x557 |

| KWG20-055 | 20 | 0.3 | 5.5 | 210 | DN80 | DN80 | 339 | 2478x385x593 |

| KWG30-075 | 30 | 0.3 | 7.5 | 258 | DN100 | DN100 | 386 | 2787x385x637 |

| KWG40-110 | 40 | 0.3 | 11 | 252 | DN100 | DN100 | 465 | 2996x400x639 |

| KWG50-110 | 50 | 0.3 | 11 | 273 | DN125 | DN125 | 608 | 3397x445x720 |

| KWG60-150 | 60 | 0.3 | 15 | 225 | DN125 | DN125 | 665 | 3427x445x720 |

| KWG70-220 | 70 | 0.3 | 22 | 230 | DN150 | DN150 | 947 | 3751x445x765 |

| KWG80-220 | 80 | 0.3 | 22 | 283 | DN150 | DN150 | 947 | 3751x445x765 |

| KWG90-220 | 90 | 0.3 | 22 | 205 | DN150 | DN150 | 947 | 3751x445x765 |

Technical Specifications of Screw Pump(Mechanical Speed Adjusting)

| Model | Flow, m3/h | Lift, m | Motor, kW | Speed, RPM | Inlet | Outlet | Weight, kg | Dimensions LxWxH, mm |

|---|---|---|---|---|---|---|---|---|

| KWG10-040V | 1-10 | 0.3 | 4 | 60-244 | DN80 | DN80 | 258 | 2165x380x557 |

| KWG20-055V | 1-20 | 0.3 | 5.5 | 60-210 | DN80 | DN80 | 339 | 2478x385x593 |

| KWG30-075V | 1-30 | 0.3 | 7.5 | 60-258 | DN100 | DN100 | 386 | 2787x385x637 |

| KWG40-110V | 1-40 | 0.3 | 11 | 60-252 | DN100 | DN100 | 465 | 2996x400x639 |

| KWG50-110V | 1-50 | 0.3 | 11 | 60-273 | DN125 | DN125 | 608 | 3397x445x720 |

| KWG60-150V | 1-60 | 0.3 | 15 | 60-225 | DN125 | DN125 | 665 | 3427x445x720 |

Technical Features of Screw Pump

- German brand, high quality, long service life.

- The rotor is made of wear-resistant alloy or stainless steel

- The stator is made of elastomer, which provides advantages when pumping liquids characterized by high viscosity and inclusions of solid phase particles suspended in the liquid

- Compliance with standards: Ex/API/ISO/EAC

For drilling mud processing, we use screw pump to transfer drilling mud into decanter centrifuge or three-phase centrifuge. International brand screw pump such as Netzsch Nemo pump or NOV Brandt Mono pump, both are single screw pumps suitable for conveying drilling mud.

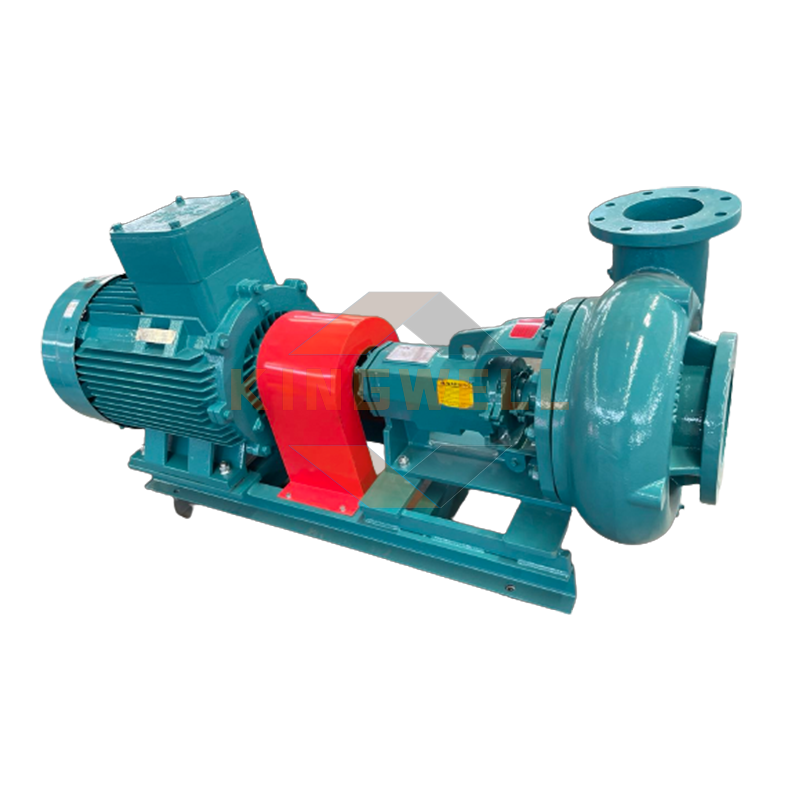

Except for screw pump, centrifugal pump is also very popular in the oil drilling mud system. Due to its excellent field design, lower cost and better anti-abrasive performance, centrifugal pump can be used to pump drilling fluid from tank compartment to the next .

Online consultation

Quick access to Technical Support and Detailed Quotations

CONTACT US

-

This email address is being protected from spambots. You need JavaScript enabled to view it. -

+86 315 2031752