PRODUCTS

- Oil Drilling rig & Equipment

- Solids Control

- Shale Shaker

- API Shaker screens

- Decanter centrifuge

- Mud Cleaner

- Desander

- Desilter

- Centrifugal Degasser

- Vacuum Degasser

- Mud Agitator

- Mud Hopper

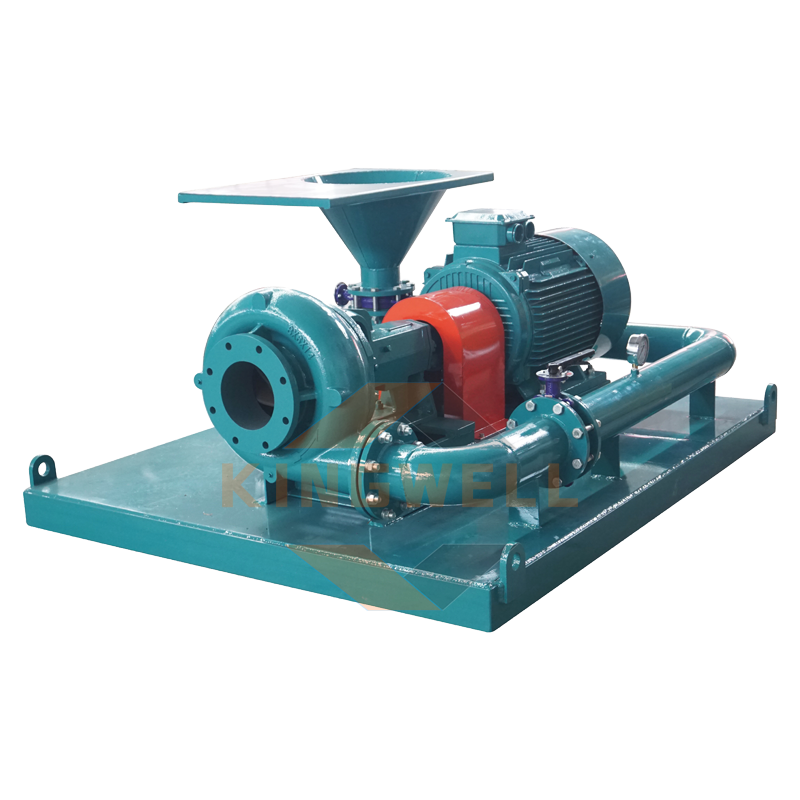

- Jet Mud Mixer

- Centrifugal Pump

- Screw Conveyer

- Screw Pump

- Submersible Slurry Pump

- Flare Ignition Device

- Mud Gun

- Mud Solids Control System

- Mud Cooling System

- Mud Tanks

- Drilling Waste Management

- Separation Technology

- Packaged Mud Recycling Systems

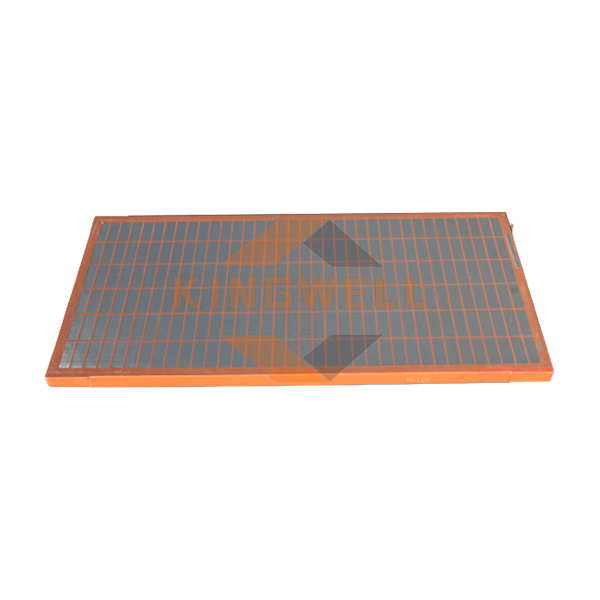

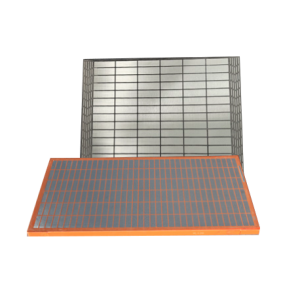

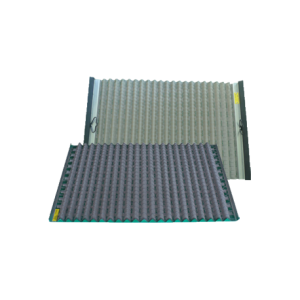

KINGWELL together with our partner can supply you with high quality and competitive various types of replacement shaker screens for shale shakers of various brands and models, which has more than 15 years of experience in the production of shaker screens. Screen is a fine mesh used to filter and separate cuttings from the drilling fluid. Selecting the correct mesh size can help ensure drilling efficiency. KINGWLL applies the most advanced technology to manufacture various shaker screens with mesh sizes from API 20 to API 400 in accordance with the requirements of API RP 13C, for shale shakers manufactured by Brandt, Derrick, M-I Swaco, etc. or as per customers' requirements.

The design of shaker screens - two-layer or three-layer, depends on the API mesh. The first layer of shaker screens is made of SS304, the second and third layers of shaker screens are made of SS304 or SS316L.

Frame screens – the frame is made of composite materials that are resistant to aggressive drilling fluids. The shelf life of screen panels with composite frame is more than 5 years. They have a usable area 10-20% larger compared to screen panels with metal frame. High-quality fiberglass is used to improve the temperature properties of the composite material, so that the frame does not change its characteristics up to 140 degrees Celsius.

Technical Specifications of Shaker Screens

| № API | Separation D100, | Screens for KMWG |

Screens for Mongoose |

Screens for King Cobra |

Screens for FLC 2000 |

Screens for FLC 500 |

|---|---|---|---|---|---|---|

| API 25 | ﹥655.0TO 780.0 | KW-024-MG | KW-024-MG | KW-024-KC | KW-024-D20 | KW-024-D50 |

| API 35 | > 462.5TO 555.0 | KW-038-MG | KW-038-MG | KW-038-KC | KW-038-D20 | KW-038-D50 |

| API 40 | > 390.0 TO 462.0 | KW-045-MG | KW-045-MG | KW-045-KC | KW-045-D20 | KW-045-D50 |

| API 50 | > 275.0 TO 390.0 | KW-050-MG | KW-050-MG | KW-050-KC | KW-050-D20 | KW-050-D50 |

| API 60 | > 231.0 TO 275.0 | KW-084-MG | KW-084-MG | KW-084-KC | KW-084-D20 | KW-084-D50 |

| API 70 | > 196.0 TO 231.0 | KW-105-MG | KW-105-MG | KW-105-KC | KW-105-D20 | KW-105-D50 |

| API 80 | > 165.0 TO 196.0 | KW-120-MG | KW-120-MG | KW-120-KC | KW-120-D20 | KW-120-D50 |

| API 100 | > 137.5 TO 165.0 | KW-165-MG | KW-165-MG | KW-165-KC | KW-165-D20 | KW-165-D50 |

| API 120 | > 116.5 TO 137.5 | KW-200-MG | KW-200-MG | KW-200-KC | KW-200-D20 | KW-200-D50 |

| API 140 | > 98.0 TO 116.5 | KW-230-MG | KW-230-MG | KW-230-KC | KW-230-D20 | KW-230-D50 |

| API 170 | > 82.5 TO 98.0 | KW-270-MG | KW-270-MG | KW-270-KC | KW-270-D20 | KW-270-D50 |

| API 200 | > 69.0 TO 82.0 | KW-325-MG | KW-325-MG | KW-325-KC | KW-325-D20 | KW-325-D50 |

| API 230 | > 58.0 TO 69.0 | KW-350-MG | KW-350-MG | KW-350-KC | KW-350-D20 | KW-350-D50 |

| API 270 | > 49.0 TO 58.0 | KW-370-MG | KW-370-MG | KW-370-KC | KW-370-D20 | KW-370-D50 |

| API 325 | > 41.5 TO 49.0 | KW-400-MG | KW-400-MG | KW-400-KC | KW-400-D20 | KW-400-D50 |

API Shaker Screens

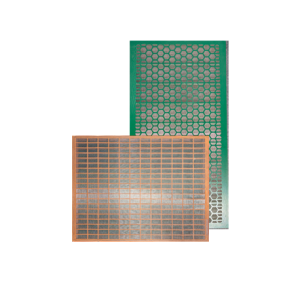

Replacement Screens for Swaco Shakers

Kingwell can supply high quality replacement screens for below shale shakers and mud cleaners: Mongoose PRO, Mongoose PT & Meerkat, MD-2/ MD-3 etc. Can be manufactured in composite or steel frame.

Remarks: The shaker brands mentioned above are trademarks of the original shaker manufacturers and are reserved by them. They are not affiliated with Kingwell. All information is for reference only.

Replacement Screens for Brandt Shakers

Kingwell can supply high quality replacement screens for below shale shakers and mud cleaners: King Cobra, Mini Cobra, Venom, LCM-2D, LCM-3D, VSM 300, D380/D285P etc. Can be manufactured in composite or steel frame.

Remarks: The shaker brands mentioned above are trademarks of the original shaker manufacturers and are reserved by them. They are not affiliated with Kingwell. All information is for reference only.

Replacement Screens for Derrick Shakers

Kingwell can supply high quality replacement screens for below shale shakers and mud cleaners: D 2000, D 500, DP600, HYP etc.

Remarks: The shaker brands mentioned above are trademarks of the original shaker manufacturers and are reserved by them. They are not affiliated with Kingwell. All information is for reference only.

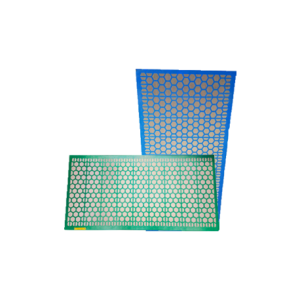

Replacement Screens for other Shakers

Kingwell can supply high quality replacement screens for chinese or other shale shakers and mud cleaners.

Notes:

All listed screens are replaceable, not original screen. In addition, Swaco, Derrick, Brandt etc. are trademarks and reserved by the original shale shaker manufacturer. All information is for reference only.

Technical Features of KINGWELL Shaker Screens

- The high quality canvas is made of SS304~SS316L.

- High conductivity and undamped area.

- Multi-level configurations.

- Fully interchangeable with original meshes.

- Custom made service available.

- Cost-effective with the best price-quality ratio.

Online consultation

Quick access to Technical Support and Detailed Quotations

CONTACT US

-

This email address is being protected from spambots. You need JavaScript enabled to view it. -

+86 315 2031752