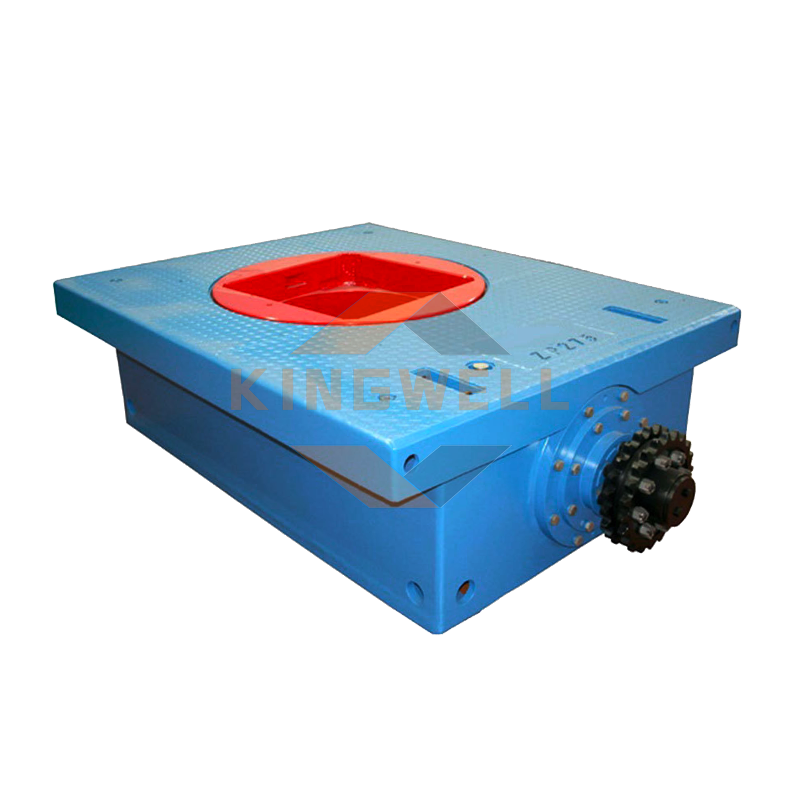

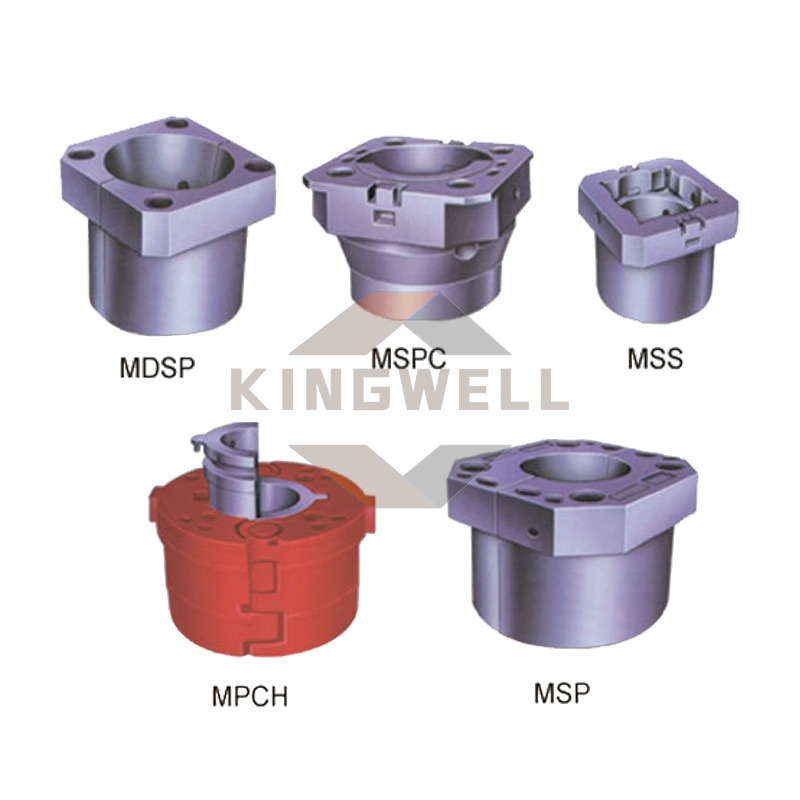

Master Bushing

The master bushing is one of the most important parts of the drilling Rotary Table, also called the large rotor bushing. The master bushings are designed to work in conjunction with the roller liners of the drilling rotor under the kelly pipe to control drill strings during oil and gas drilling. The master bushing is designed and manufactured to API Spec 7K.

These series of rotary bushing are suitable for API standard drill pipe slips, drill collar slips, casing slips and roller bushing, with two structures: solid body and split body. Two drive types are available: pin driven and square driven. It is designed and manufactured according to API Spec 7K.

Technical Parameters for Master Bushing

| Model | Rotary table size (in) | Insert bowl | Tubular OD (in) |

| MDSP(Split) | 17 1/2 | - | 2 3/8-8 5/8 |

| 20 1/2 | - | 2 3/8-8 5/8 | |

| MSP(Split) | 27 1/2 | - | 2 3/8-8 5/8 |

| MSPC(Solid) | 20 1/2- 22 1/2 | Insert bowl 1809 | 2 3/8-8 5/8 |

| Insert bowl 1902 | 9 5/8-10 3/4 | ||

| Master bushing1805-1 | 11 3/4-13 3/8 | ||

| Master bushing19333 | 11 3/4-13 3/8 | ||

| 23-27 1/2 | No.3 Insert bowl 1810 | 2 3/8-8 5/8 | |

| No.2 Insert bowl 1904 | 9 5/8-10 3/4 | ||

| No.2 Insert bowl 1903 | 11 3/4-13 3/8 | ||

| MSS(Split) | 17 1/2—27 1/2 | - | 2 3/8-7 5/8 |

| MSS(Solid) | 17 1/2—23 | Insert bowl 1011 | 2 3/8-7 5/8 |

| Extended insert bowl 1024 | 2 3/8-8 5/8 | ||

| 27 1/2 | Insert bowl 1022 | 2 3/8-7 5/8 | |

| Extended insert bowl 1025 | 2 3/8-8 5/8 | ||

| Insert bowl 1026 | 9 5/8-10 3/4 | ||

| Insert bowl 2002 | 11 3/4-13 3/8 | ||

| MPCH | 37 1/2 | No.3 Insert bowl 6608 | 2 3/8-8 5/8 |

| No.2 Insert bowl 6609 | 9 5/8-10 3/4 | ||

| No.2 Insert bowl 6610 | 11 3/4-13 3/8 | ||

| 49 1/2 | MPCH37 1/2 | 2 3/8-13 3/8 |

Technical Features for Master Bushing

- Master Bushing is made of casting alloy steel, the rotary table diameter of the main rotor liner (including coupling) ranges from 17 1/2 inches to 37 1/2 inches.

- According to the design, the master bushing are divided into two types: solid body and split body.

- According to the oil displacement method, the inserts are divided into contact-driven rotor main liner and square shank rotor main liner. According to the API standard, they are suitable for drill pipe clamping dies in the rotor, wedge grip dies, drill collar weighted wedges, and rotor inserts for the guide pipe.

Online consultation

Quick access to Technical Support and Detailed Quotations

Please fill out the form below so that we can quickly answer your questions and provide you with our high-quality technical support. You can also contact us through email, and our team will provide you with excellent service.

CONTACT US

-

This email address is being protected from spambots. You need JavaScript enabled to view it. -

+86 315 2031752