Decanter centrifuge

PRODUCTS

- Oil Drilling rig & Equipment

- Solids Control

- Shale Shaker

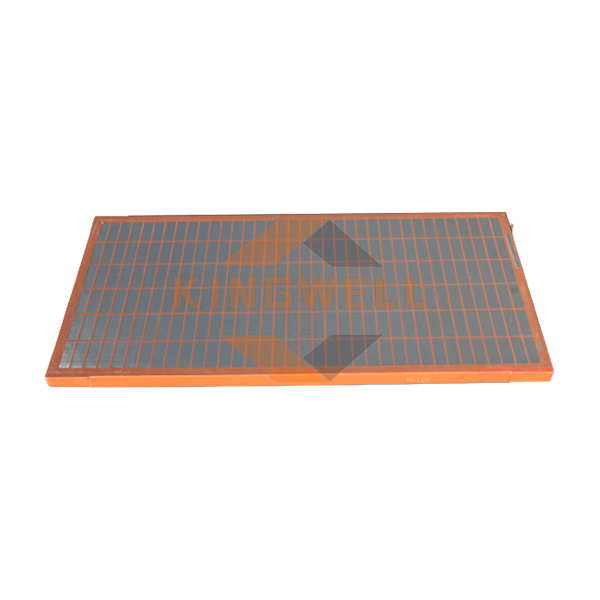

- API Shaker screens

- Decanter centrifuge

- Mud Cleaner

- Desander

- Desilter

- Centrifugal Degasser

- Vacuum Degasser

- Mud Agitator

- Mud Hopper

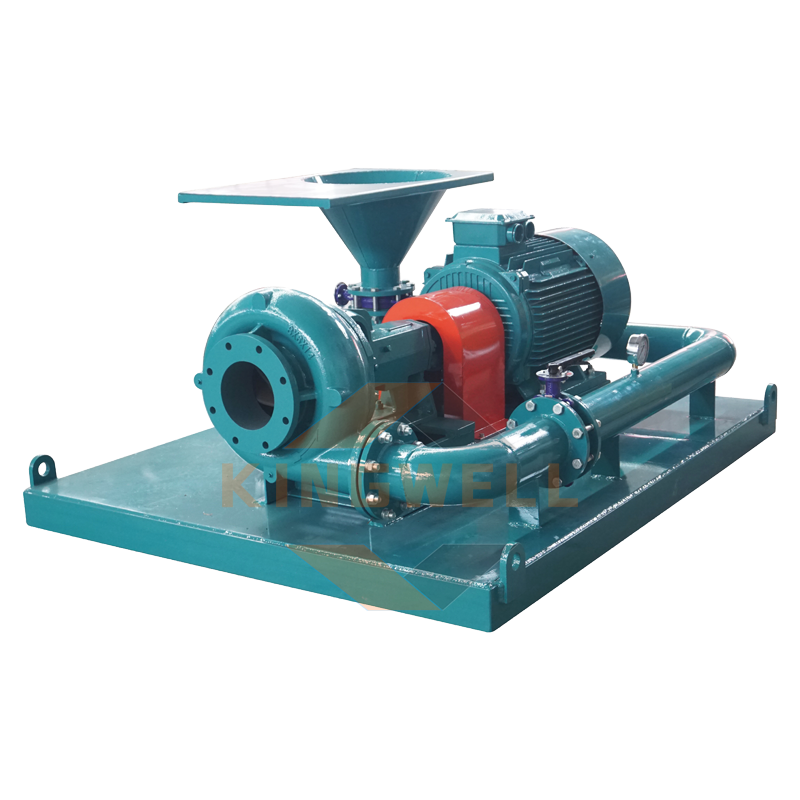

- Jet Mud Mixer

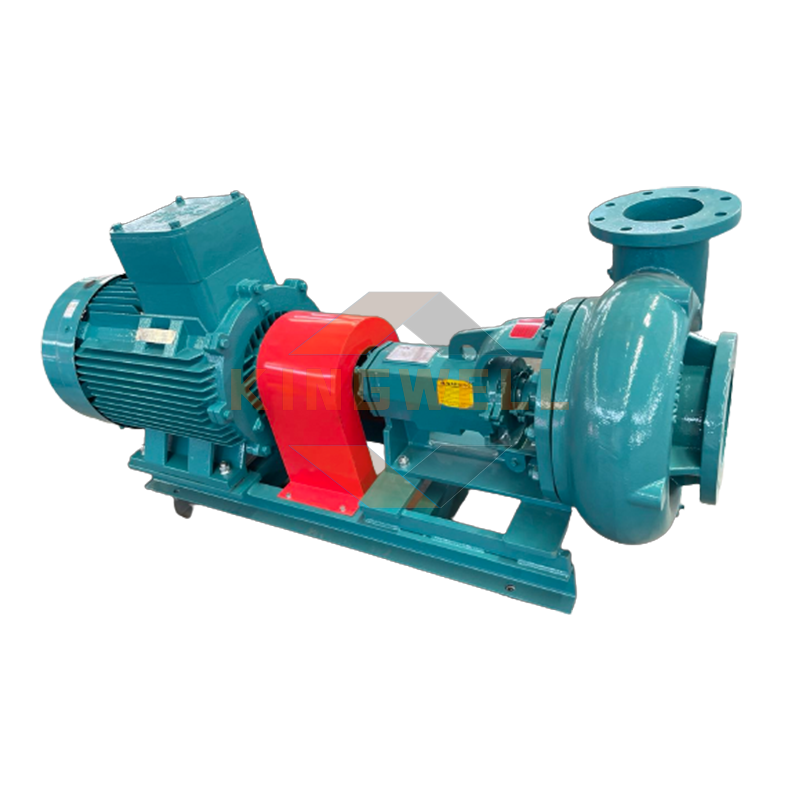

- Centrifugal Pump

- Screw Conveyer

- Screw Pump

- Submersible Slurry Pump

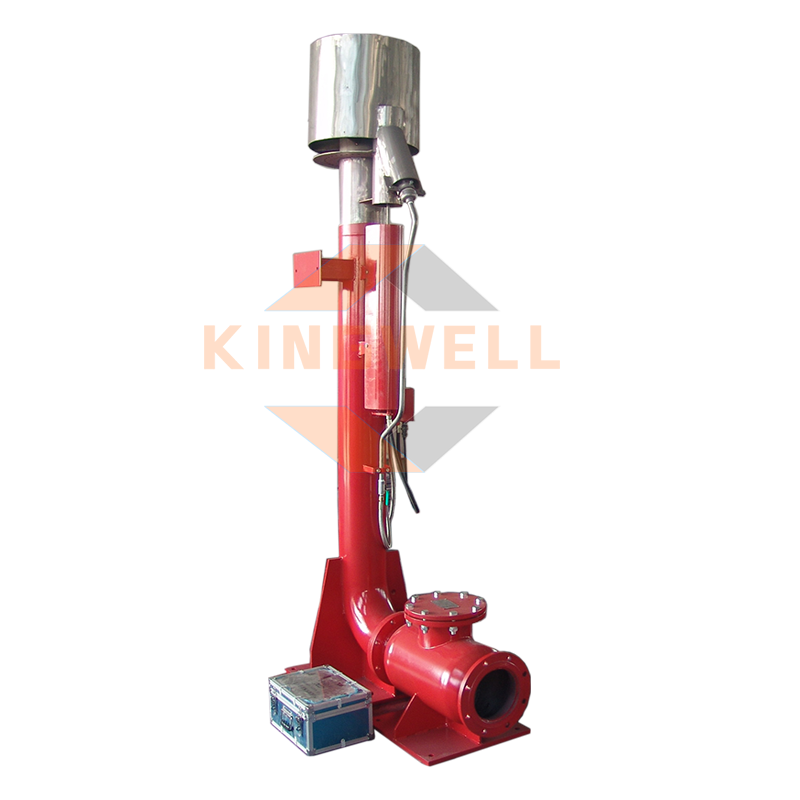

- Flare Ignition Device

- Mud Gun

- Mud Solids Control System

- Mud Cooling System

- Mud Tanks

- Drilling Waste Management

- Separation Technology

- Packaged Mud Recycling Systems

High-performance decanter centrifuge KWLW series is designed for highly efficient solids separation from water-based or oil-based mud in oil and gas drilling. With reasonable oilfield design and strong production material, decanter centrifuge KWLW can work perfectly to achieve the drilling purpose.

Decanter centrifuge KWLW series is also popular used for drilling waste treatment, oil sludge treatment, tank cleaning, barite recover, low gravity and high gravity solid separation, dewatering, etc. The decanter centrifuge ensures finer solid separation from drilling mud, which is larger than 2-5 microns. KWLW Decanter Centrifuge can be used for onshore drilling and offshore drilling rig platform, and middle speed centrifuge with 1600RPM~2000RPM to recover barite & high-speed centrifuge with 2500RPM~2800RPM to cut mud weight

All main parts of the decanter centrifuge, such as the bowl, screw are made of stainless steel. Balancing of centrifuge reduces noise and vibration. The service life of the screw is increased due to the use of brazed plates made of wear-resistant tungsten carbide.All electrical equipment of centrifuges is explosion-proof, which allows them to be used in well drilling conditions.

Technical parameters of Decanter centrifuge KWLW series

| Model | KWLW25 | KWLW35 | KWLW35VFD | KWLW35FHD | KWLW45N2 | KWLW45N3 | KWLW53 |

|---|---|---|---|---|---|---|---|

| Drive type | Electric fixed/VFD or Hydraulic | Electric fixed | Electric VFD | Hydraulic | Electric fixed/VFD | ||

| Bowl Diameter, mm | 250 | 355 | 355 | 355 | 450 | 450 | 530 |

| Bowl Length, mm | 670/880 | 1257 | 1257 | 1257 | 1000 | 1250 | 1320 |

| Max Capacity, m3/h | 6 | 45 | 45 | 45 | 50 | 60 | 65 |

| Max Bowl Speed, RPM | 4500 | 3900 | 3900 | 3900 | 2400 | 3500 | 2400 |

| Typical Bowl Speed, RPM | 3800 | 3200 | 0~3200 | 0~3200 | 2200 | 3000 | 2200 |

| G Force | 1777 | 2035 | 0~2035 | 0~2035 | 1215 | 2250 | 1817 |

| Cut Point, Microns | 2~5 | 2~5 | 2~5 | 2~5 | 5~7 | 2~5 | 2-5 |

| Main Motor, kW | 11 | 30 | 30 | 37 | 37 | 37 | 55 |

| Back Drive Motor, kW | N/A or 5.5 | 7.5 | 7.5 | N/A | 7.5 | 11 | 22 |

| Weight, kg | 850 | 3000 | 3200 | 4500 | 2800 | 3200 | 4000 |

| Dimensions (LхWхH), mm | 1924x1050x725 | 2960x1476x1720 | 2960x1476x1720 | 3100x1650x1700 | 2750×1550×1700 | 2900×1550×1650 | 3300×1700×1750 |

Technical Features of Decanter centrifuge KWLW series

- The cylindrical and conical bowl are made of SS316L or duplex stainless steel SS2205. Other parts of the bowl are made of SS304 stainless steel to ensure reliable operation and long service life.

- The screw protection is made of tungsten carbide, which ensures a long service life.

- The liquid discharge and solid discharge are protected by carbide inserts made of tungsten carbide.

- SKF/FAG bearing for longer and reliable operation.

- A VFD control pannel allows you to smoothly adjust the operating mode of the centrifuge and select the optimal performance depending on the type and composition of the drilling fluid.

- The adjustable height of liquid discharge in bowl ensures an optimal balance between the purity of the discharged liquid and the dryness of the discharged solid phase

- Compliance with standards: Ex/API/ISO/EAC

- Electrical elements: SIEMENS, Schneider, ABB or CHINT, etc.

Online consultation

Quick access to Technical Support and Detailed Quotations

CONTACT US

-

This email address is being protected from spambots. You need JavaScript enabled to view it. -

+86 315 2031752