Screw Press

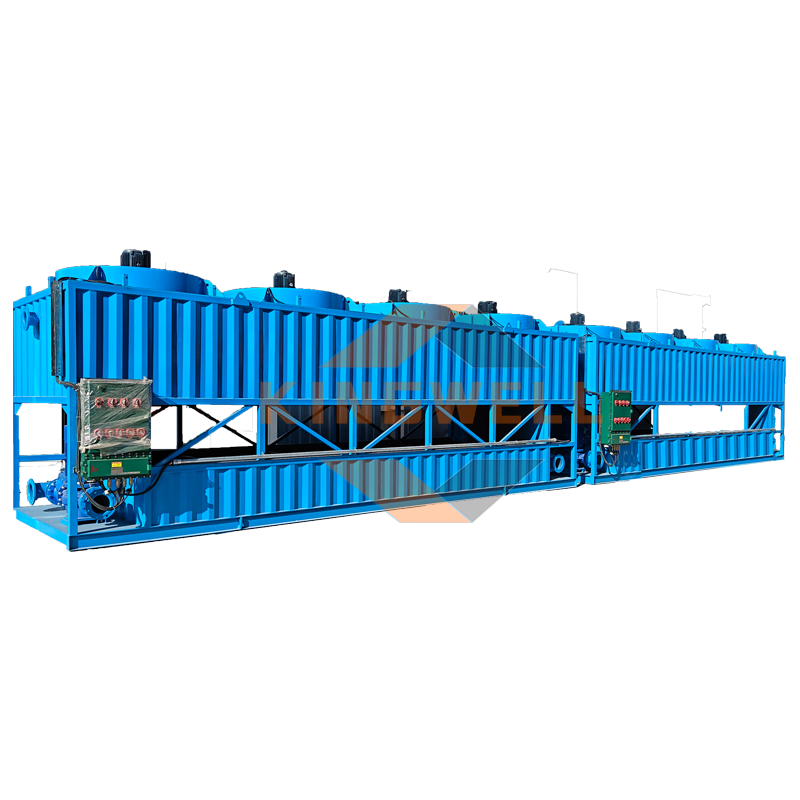

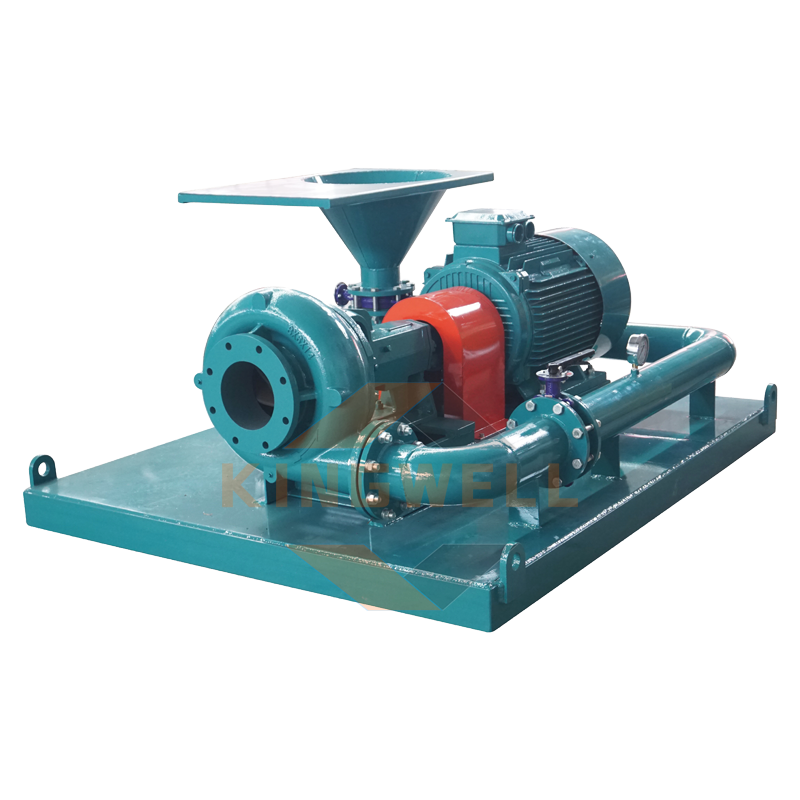

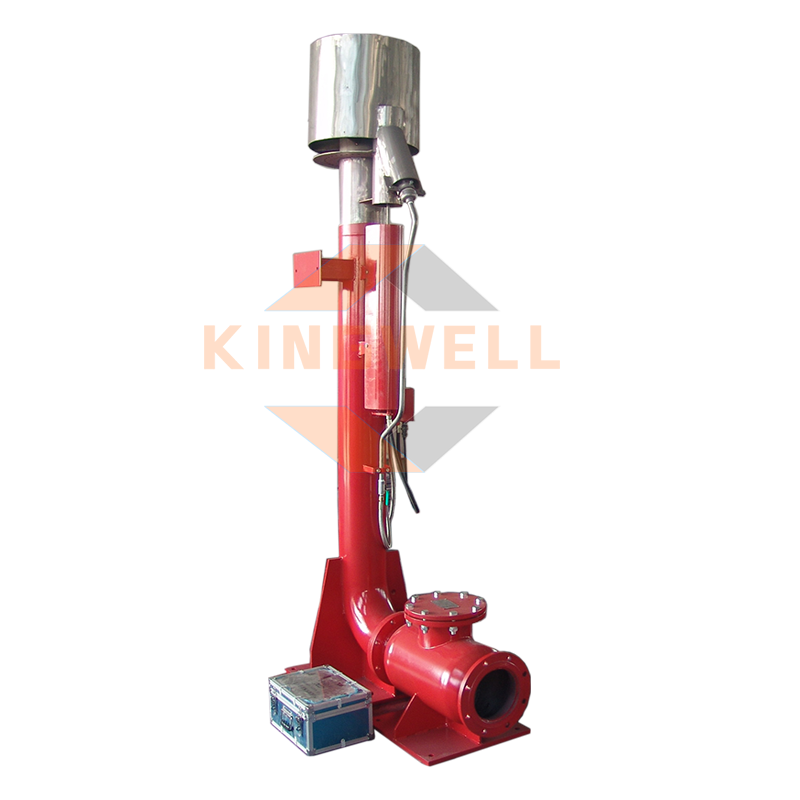

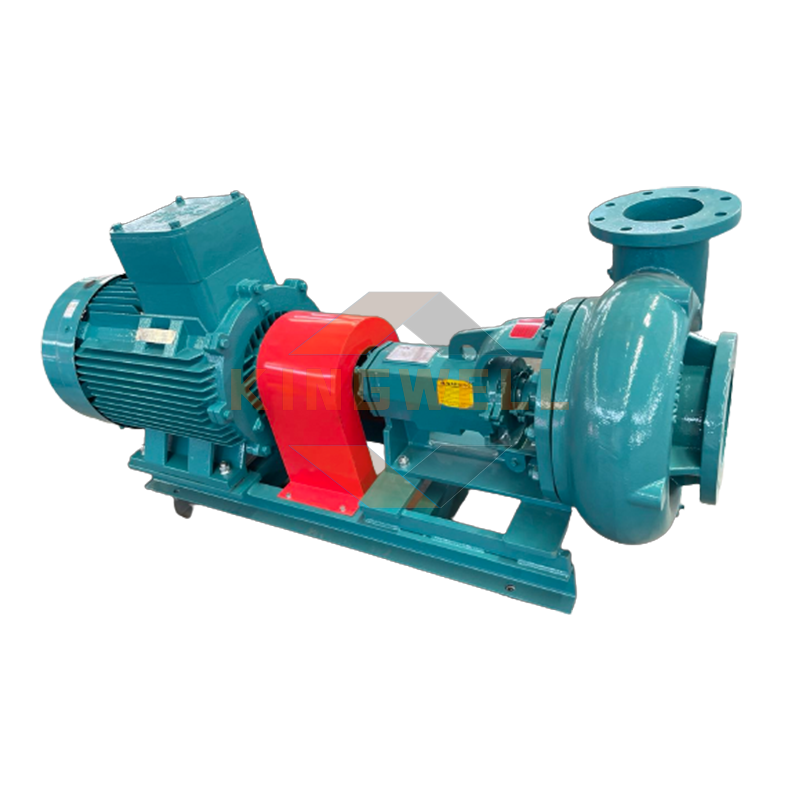

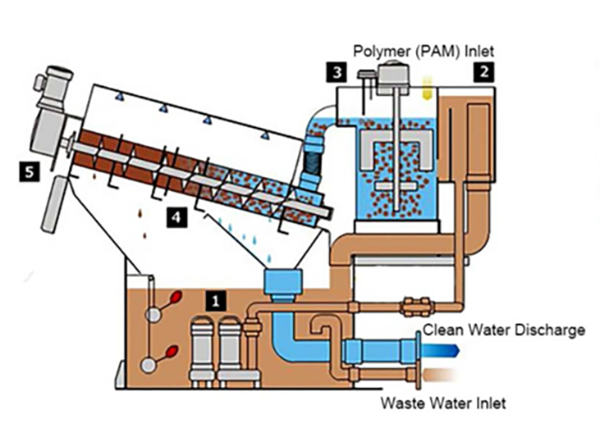

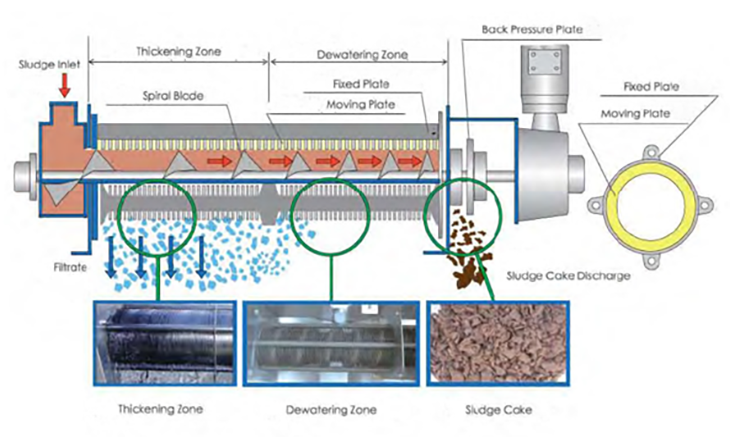

KINGWELL Screw Press is a cost-effective sludge dewatering equipment that uses the principle of screw extrusion, through the strong compressive force generated by changing the screw diameter and screw pitch, and the tiny gap between the floating ring and the fixed ring. The screw dehydrator consists of a dewatering drum, a dosing tank, a flocculation tank, and a control cabinet. The dewatering drum thickens and dewaters the sludge; in the dosing tank, the required amount of sludge flows through a V-shaped overflow into the flocculation tank, where the sludge is mixed with the reagent. The control cabinet provides control over the system operation in manual/automatic mode. Widely used in wastewater treatment projects in municipal, aquaculture, food, starch, petroleum, pharmaceutical, chemical, paper, leather and other industries

Working principle of Screw Press

Technical parameters for Screw Press

| Model | Screw Dia. mm | Screw Nos. | Power KW | Agitator Power KW | Pressure Mpa | Flushing Water L/H | Weight kg | Standard Capacity (For Dry Solids) Kg/h | Capacity for Sludge with Different Concentration | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10000 mg/L | 20000 mg/L | 30000 mg/L | 40000 mg/L | 50000 mg/L | |||||||||

| KWDL101 | 100 | 1 | 0.18 | 0.18 | 0.1-0.2 | 24 | 220 | 5~7 | ~0.5m³/h | ~0.25m³/h | ~0.2m³/h | ~0.15m³/h | ~0.14m³/h |

| KWDL201 | 200 | 1 | 0.37 | 0.18 | 32 | 420 | 15~20 | ~1.5m³/h | ~0.75m³/h | ~0.6m³/h | ~0.5m³/h | ~0.4m³/h | |

| KWDL202 | 2 | 0.74 | 0.55 | 64 | 550 | 30~40 | ~3m³/h | ~1.5m³/h | ~1.2m³/h | ~1m³/h | ~0.8m³/h | ||

| KWDL203 | 3 | 1.11 | 0.55 | 96 | 700 | 45~60 | ~4.5m³/h | ~2.25m³/h | ~1.8m³/h | ~1.5m³/h | ~1.2m³/h | ||

| KWDL301 | 300 | 1 | 0.75 | 0.55 | 40 | 900 | 50~70 | ~5m³/h | ~2.5m³/h | ~2m³/h | ~1.5m³/h | ~1.4m³/h | |

| KWDL302 | 2 | 1.5 | 0.75 | 80 | 1400 | 100~140 | ~10m³/h | ~5m³/h | ~4m³/h | ~3m³/h | ~2.8m³/h | ||

| KWDL303 | 3 | 2.25 | 1.1 | 120 | 1900 | 150~210 | ~15m³/h | ~7.5m³/h | ~6m³/h | ~4.5m³/h | ~4.2m³/h | ||

| KWDL304 | 4 | 3 | 1.1 | 160 | 2500 | 200~280 | ~20m³/h | ~10m³/h | ~8m³/h | ~6m³/h | ~5.6m³/h | ||

| KWDL401 | 400 | 1 | 1.5 | 1.1 | 80 | 2200 | 130~160 | ~13m³/h | ~6.5m³/h | ~5m³/h | ~4m³/h | ~3.2m³/h | |

| KWDL402 | 2 | 3 | 1.5 | 160 | 3500 | 260~320 | ~26m³/h | ~13m³/h | ~10m³/h | ~8m³/h | ~6.4m³/h | ||

| KWDL403 | 3 | 4.5 | 2x1.1 | 240 | 5500 | 390~480 | ~39m³/h | ~19.5m³/h | ~15m³/h | ~12m³/h | ~9.6m³/h | ||

| KWDL404 | 4 | 6 | 2x1.1 | 320 | 7000 | 520~640 | ~52m³/h | ~26m³/h | ~20m³/h | ~16m³/h | ~12.8m³/h | ||

Online consultation

Quick access to Technical Support and Detailed Quotations

CONTACT US

-

This email address is being protected from spambots. You need JavaScript enabled to view it. -

+86 315 2031752