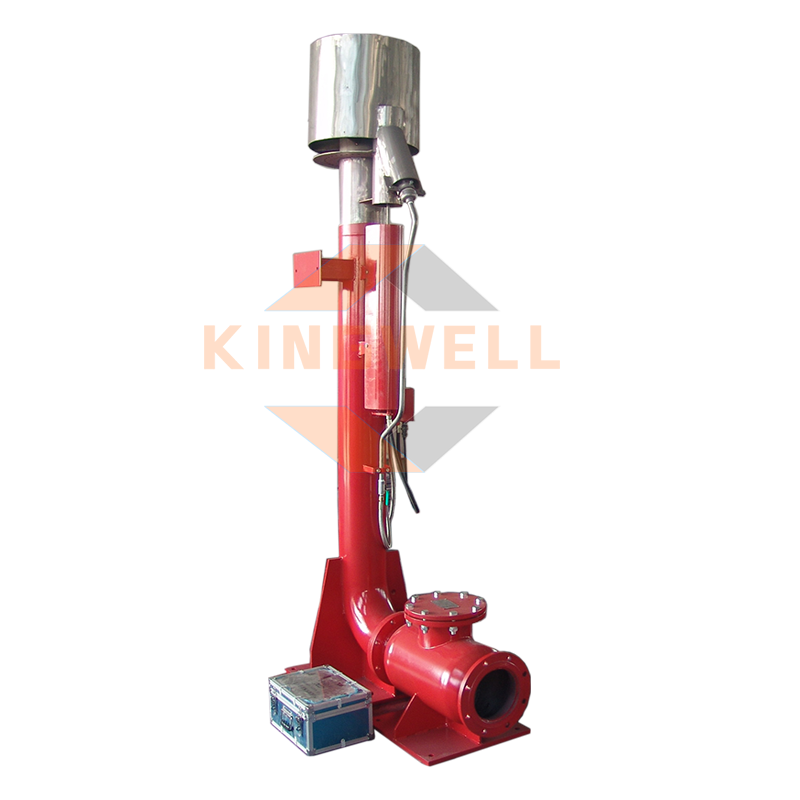

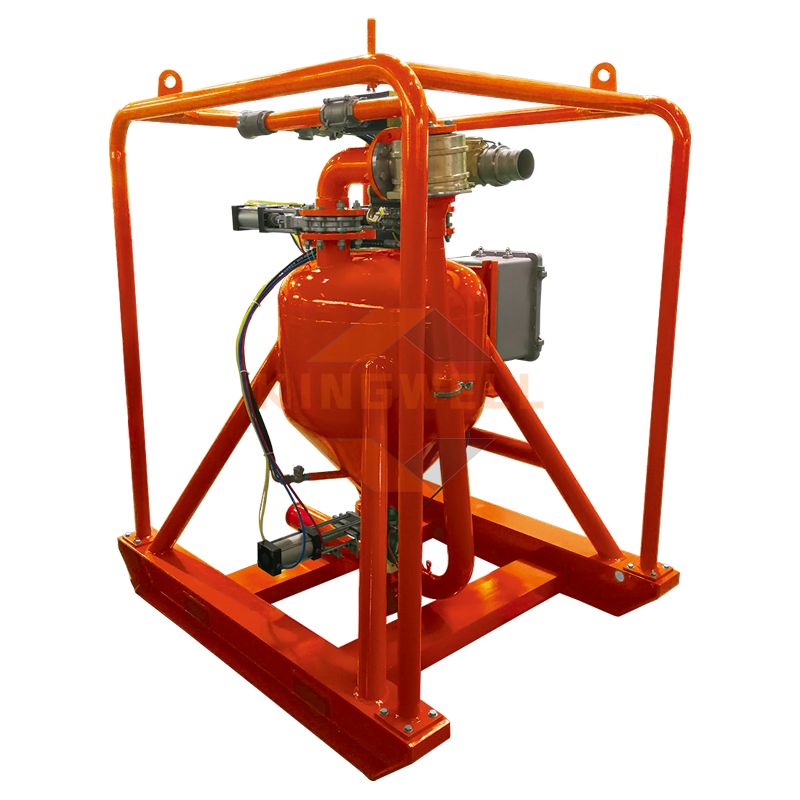

Pneumatic Slurry Pump

The pneumatic slurry pump with its special design can be used in harsh environments, with high working efficiency and lower operating costs. Capable of pumping solids, powders, liquids and solid-liquid mixtures. The pneumatic slurry pump can pump material with high density, solid content up to 80%. The vacuum degree is up to 25 inches of mercury (vacuum degree 85 kPa), and the height of the discharged water is 80 meters. In the petroleum industry, it is often used for drilling cuttings transport, oil sludge transport, tank cleaning operations, long distance waste transport, and mineral and waste transport. In addition, it is also widely used for solid transport, solid-liquid mixture transport and vacuum extraction in chemical, mining and industrial fields.

Technical Specifications of Pneumatic Slurry Pump

| Model | KWSP40 | KWSP20 | KWSP10 |

|---|---|---|---|

| Max. capacity,m3/h | 40 | 20 | 10 |

| Inlet/outlet, Inch | 4” (114mm) | 4” (114mm) | 3” (89mm) |

| Vacuum degree | 25”HG (Mercury column) | 85Kpa/25 inch HG(Mercury column) | |

| Max suction distance,m | 50m | ||

| Max. discharge distance, m | 1000 | 500 | |

| Max. solids content | 80% | ||

| Max solids size,mm | 75 | 50 | |

| Working pressure | 550Kpa-785Kpa (80-114PSI) | 550Kpa-690Kpa (80-100PSI) | |

| Air demand | 17m³/min (600CFM) | 8 m³/min (280CFM) | 4.3 m³/min (150CFM) |

| Weight, kg | 892 кг | 386кг | 320кг |

| Dimension, mm | 1690×1468×1983 | 1421×900×1448 | 1283×800×1370 |

What materials can the pneumatic slurry pump use?

- Ddrilling fluid and drill cuttings in oil drilling

- Tailings sludge

- Mud pit waste

- Hazardous waste recycling

- Oil sludge waste

- Oil sludge at the bottom of the tank.

- Waste on the bottom of transport ships

- Sand, fine sand and frac sand

- Animal feces

Technical Advantages of pneumatic slurry pump

- Pneumatic control, does not require electrical power, suitable for use in explosion-proof areas.

- Strong self-priming ability, long transportation distance, suction distance up to 50m, discharge distance up to 1000m.

- Capable of transporting liquids, mixed liquids, solids and other materials with a wide range of applications.

- The maximum diameter of transported solid materials is 50-75 mm, as well as mixed liquids with a solid content of up to 80%.

- Compact design and easy to move

- The tank has no parts, long service life and easy maintenance.

- It can operate automatically and continuously, and operation and maintenance are convenient and simple.

Online consultation

Quick access to Technical Support and Detailed Quotations

CONTACT US

-

This email address is being protected from spambots. You need JavaScript enabled to view it. -

+86 315 2031752