Vacuum Degasser

PRODUCTS

- Oil Drilling rig & Equipment

- Solids Control

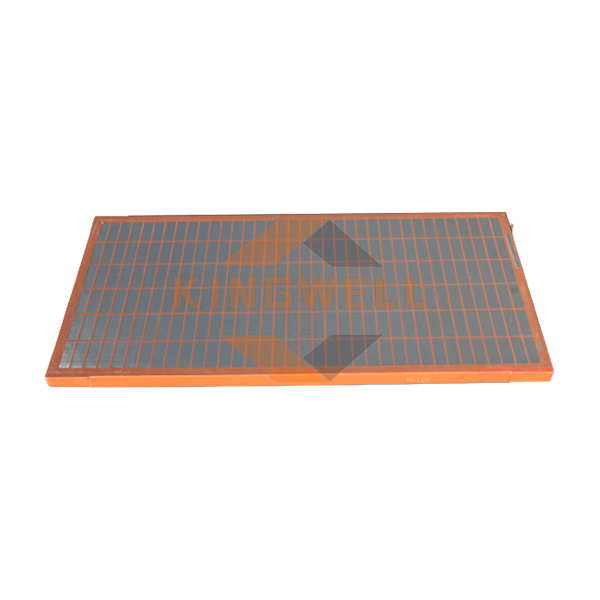

- Shale Shaker

- API Shaker screens

- Decanter centrifuge

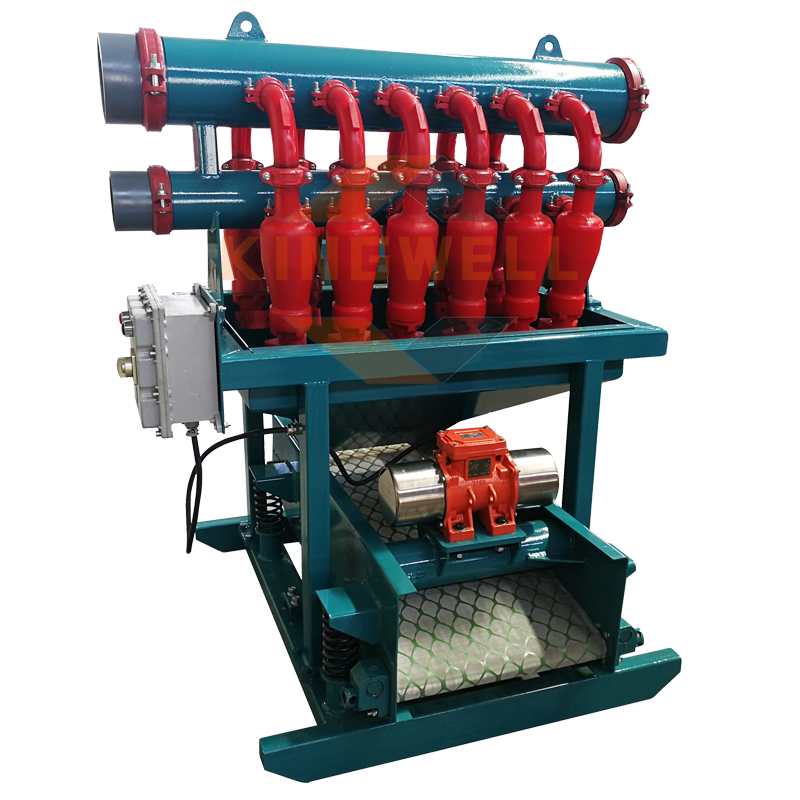

- Mud Cleaner

- Desander

- Desilter

- Centrifugal Degasser

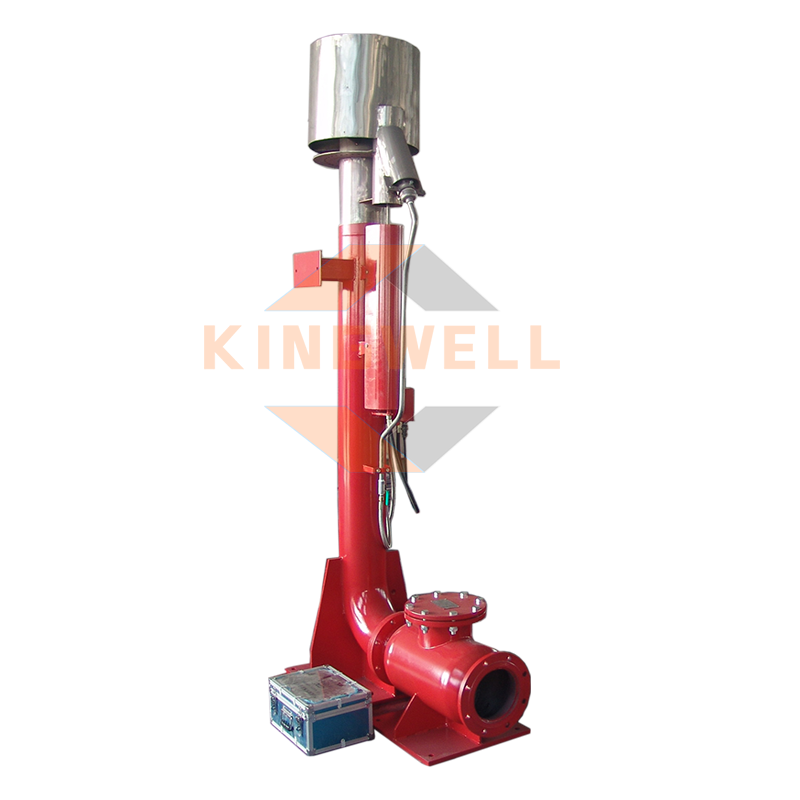

- Vacuum Degasser

- Mud Agitator

- Mud Hopper

- Jet Mud Mixer

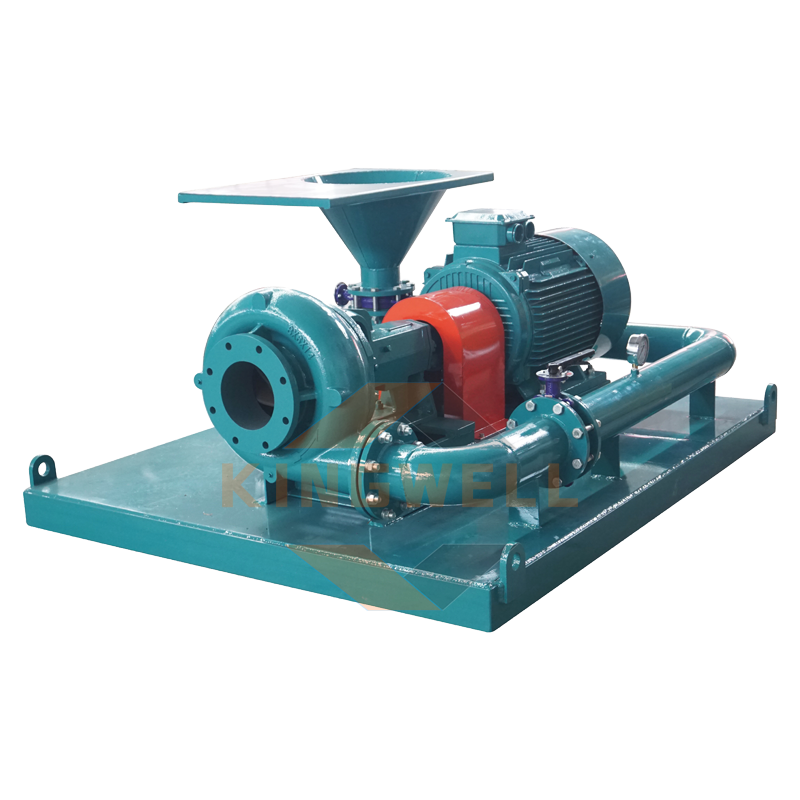

- Centrifugal Pump

- Screw Conveyer

- Screw Pump

- Submersible Slurry Pump

- Flare Ignition Device

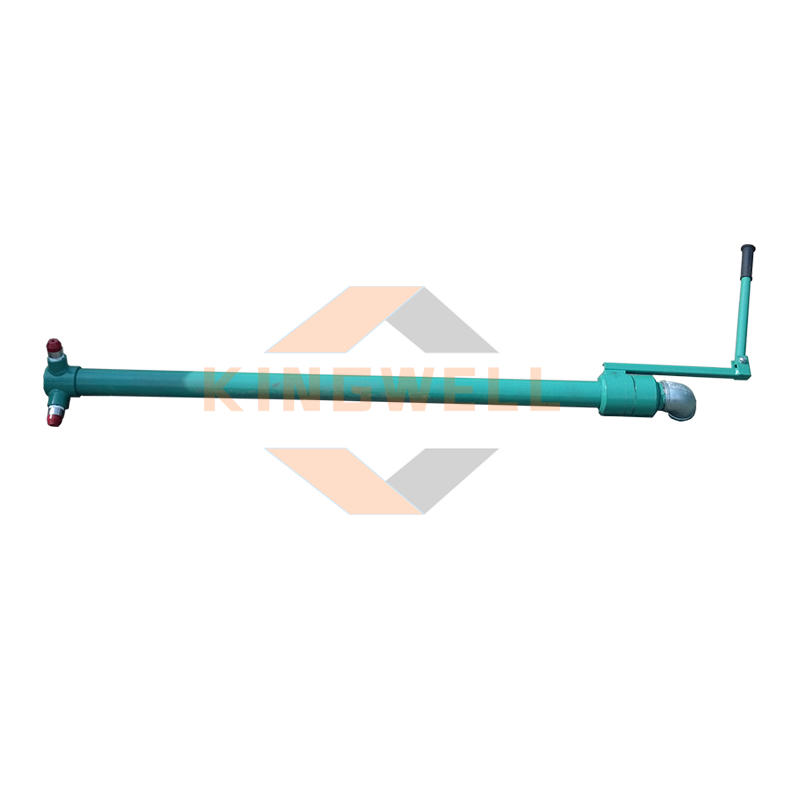

- Mud Gun

- Mud Solids Control System

- Mud Cooling System

- Mud Tanks

- Drilling Waste Management

- Separation Technology

- Packaged Mud Recycling Systems

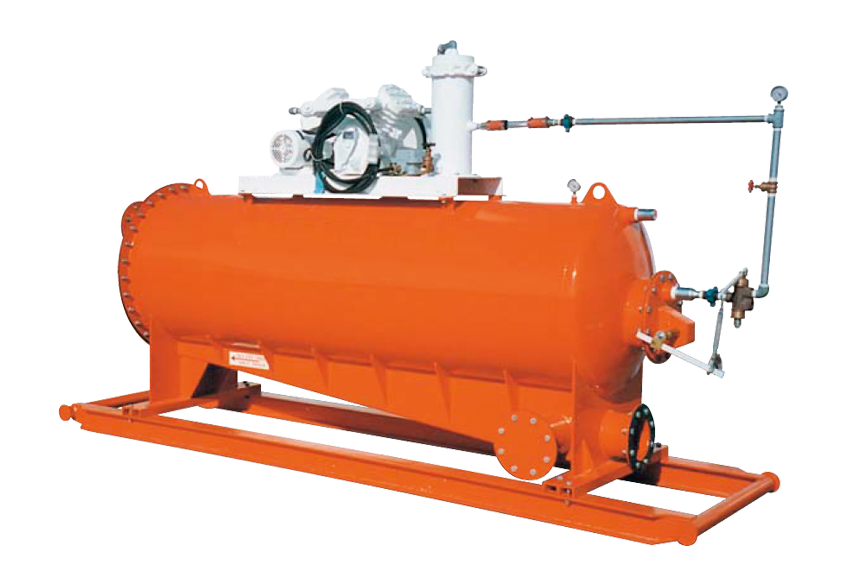

Vacuum Degasser is designed for removing the gas phase from the drilling mud. Vacuum degasser is very important for returning mud gravity, stabilizing mud viscosity and reducing drilling cost. Vacuum degasser is usually installed directly after shale shaker. And it can also be used as a high-power mixer for preparing drilling fluid. The vacuum degasser design of the structure is scientific and rational. So we are able to achieve an effective gas-liquid separation, filter out impurities and to ensure that the exhaust pipe is always smooth.

Technical parameters of Vacuum Degasser

| Model | KWZCQ240 | KWZCQ270 | KWZCQ300 | KWZCQ360 |

|---|---|---|---|---|

| Capacity, m3/h | 240 | 270 | 300 | 360 |

| Vacuum Degree, MPa | 0,020~0,040 | |||

| Ratio | 1,68 | 1,68 | 1,68 | 1,72 |

| Handling Effiiency | ≥95% | ≥95% | ≥95% | ≥95% |

| Main Motor Power, kW | 15 | 22 | 30 | 37 |

| Pump Motor Power, kW | 2.2 | 3 | 4 | 5,5 |

| Rotation Speed, RPM | 860 | 870 | 876 | 880 |

| Dimensions, mm | 1750×900×1510 | 1950×1010×1680 | 2250×1235×1650 | 2250×1500×1900 |

| Weight, kg | 1200 | 1450 | 1960 | 2510 |

KINGWELL vacuum degassers use the suction effect of vacuum pump to create negative pressure inside the vacuum bak, the drilling fluid is injected into the hollow rotor shaft through the suction pipe under atmospheric pressure. The drilling fluid is then supplied to the chamber walls through the outlet holes of the hollow shaft. The drilling fluid is separated into thin layers and the gas contained in the suspension is released. The gas enters the safe area from the gas separator through a vacuum pump and a gas-water separator. The drilling fluid is released out of the chamber using an impeller. When the main motor is started, the impeller associated with the motor is rotated at high speed so that the drilling fluid enters the chamber only from the suction pipe and does not enter the fluid discharge pipe.

The KINGWELL vacuum degasser has the following functions:

- Restoring the specific gravity of drilling fluids after their rough cleaning from drill cuttings

- separation of associated gases from the drilling fluid and their direction into the gas-air line

- Use either as the first stage of cleaning the solution from gas, or as the second stage after the gas separator (in the case of drilling method with equilibrium and unbalanced pressure in the well)

- It can be used as a high-power mixer to be combined with a circulation cleaning system for all solutions.

In addition to the above degassers, we can provide degassers similar to Derrick and a horizontal degasser similar to Swaco

Online consultation

Quick access to Technical Support and Detailed Quotations

CONTACT US

-

This email address is being protected from spambots. You need JavaScript enabled to view it. -

+86 315 2031752