Phase Decanter Centrifuge

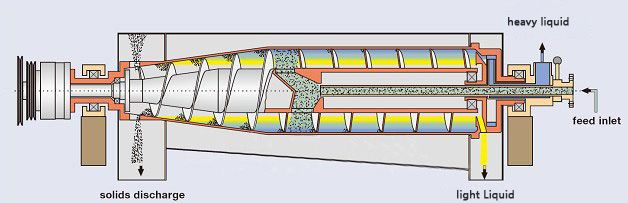

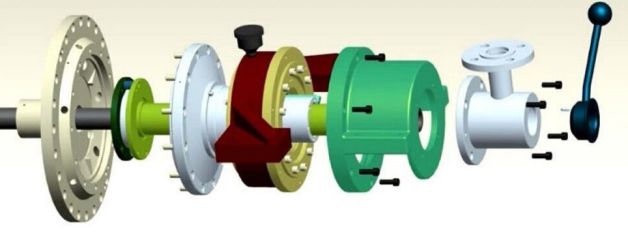

3 Phase Decanter Centrifuge KWLWS is also called tricanter, is widely used for oil, water, solids separation industry. KWLWS Series Three-phase Decanter Centrifuge is mainly composed of rotating body assembly, planetary gear differential, motors, double frequency converters, base, fully-closed housing, feeding pipe assembly, and automatic control system, and can perform liquid-liquid-solid or liquid-solid-liquid three-phase separation for multiple suspensions with large differences in materials.

3 Phase Decanter Centrifuge KWLWS often is used in three-phase separation of food waste, edible oil separation, industrial waste oil separation, coal tar separation, yeast and starch separation etc.

Working principle of 3 Phase Decanter Centrifuge

3 Phase Decanter Centrifuge is turned on and automatically up to preset speed. Then open the feeding valve and the suspension is pumping into the rotating body assembly. The suspension in bowl is divided into three phases quickly under the action of centrifugal force. The differential action of differential gear makes relative movement generated between screw and bowl, and the heaviest solid phase settles on inner bowl wall and is pushed to discharged through drainage port. At the same time, the heavier liquid phase (such as water) is close to inner bowl wall while lighter liquid phase (such as oil) is distant from inner bowl wall. The overflow baffle plate can adjust and realize the separation effect of different sediments and liquid phases. The separated light liquid is discharged through overflow port while the separated heavy liquidis discharged by centripetal pump at big end of basket

Technical Parameters for 3 Phase Decanter Centrifuge

| Model | KWLWS35 | KWLWS45 | KWLWS52 | KWLWS62 |

| Bowl Diameter, mm | 350 | 450 | 520 | 620 |

| Bowl length, mm | 1540 | 1800 | 2132 | 2480 |

| L/D Ration | 4.27 | 4 | 4.1 | 4 |

| Ma Capacity, m3/h | 5 | 10 | 15 | 25 |

| Max Bowl Speed, RPM | 4000 | 3600 | 3000 | 2800 |

| Max G Force, G | 3136 | 3260 | 2620 | 2720 |

| Differential speed, rpm | 1-25 | 1-25 | 1-25 | 1-25 |

| Lubricant type | Grease lubrication | Oil lubrication | ||

| Main Motor, KW | 22 | 37 | 55 | 90 |

| Back Motor, KW | 5.5 | 15 | 15 | 22 |

Technical Features for 3 Phase Decanter Centrifuge

- The material of decanter centrifuge bowl is made of duplex stainless steel SS2205 or SS2304, etc. using centrifugal casting and forging method to ensure high quality and long service life.

- The screw is made of duplex stainless steel SS2205 or SS2304. Heat treatment after welding to ensure high quality and long service life

- SKF or FAG brand bearings to ensure reliable performance.

- Balancing during the production to ensure the stable operation of the centrifuge under the high speed working condition

- The screw propeller is protected by replaceable wear-resistant alloy plate with long service life and easy maintenance.

- The wear-resistant sleeve of the solid discharge port is a special hard tungsten carbide sleeve, of which the wear resistance is extremely high, and not fragile

- Intelligent electrical control system: Use HMI+PLC automatic control, with frequency converters ABB, Siemens, etc.

Centripetal pump of 3 Phase Decanter Centrifuge

Online consultation

Quick access to Technical Support and Detailed Quotations

CONTACT US

-

This email address is being protected from spambots. You need JavaScript enabled to view it. -

+86 315 2031752