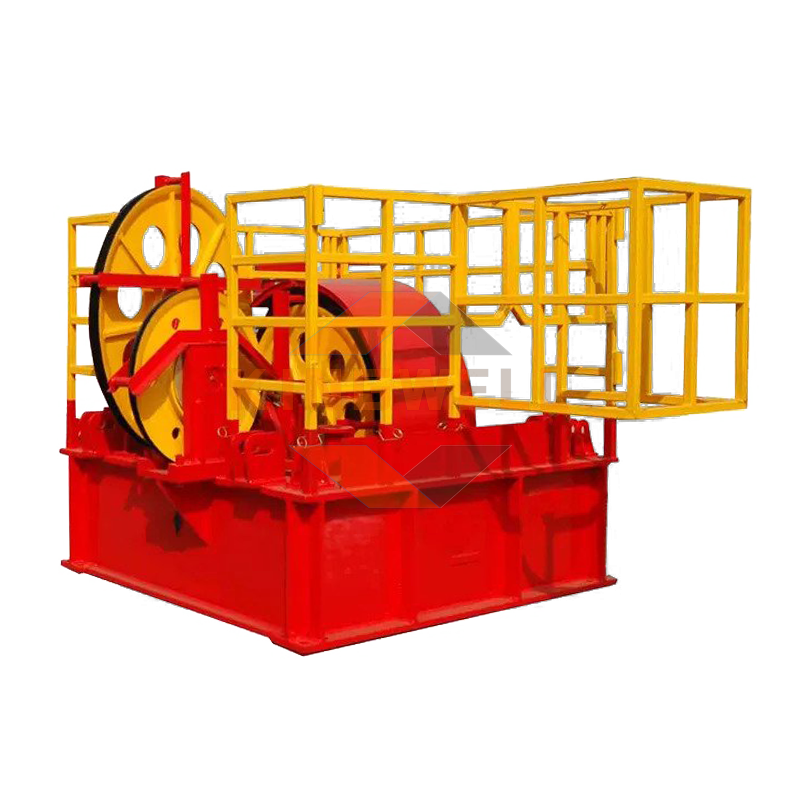

The crown block is a stationary part of the traveling system for drilling rig, and is installed on the head of the drilling derrick. The crown block is used in the oil and gas field to solve problems of supporting tools or casing pipes, and also for various technological and hoisting operations when drilling wells. Includes one or more rollers mounted on a single frame installed on the crown block platform of the tower. Drilling crown block include:

- Crown block axis

- Crown block frame

- Pulley sections

- Auxiliary pulleys

- Safety cover

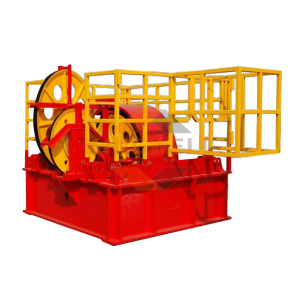

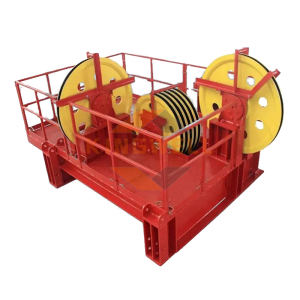

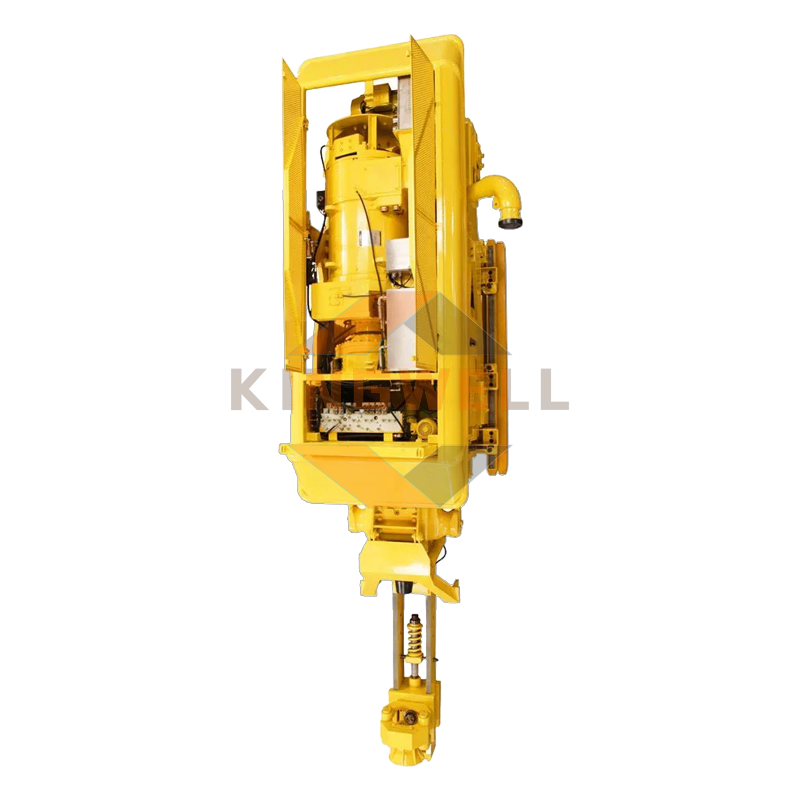

Crown Block for drilling rig

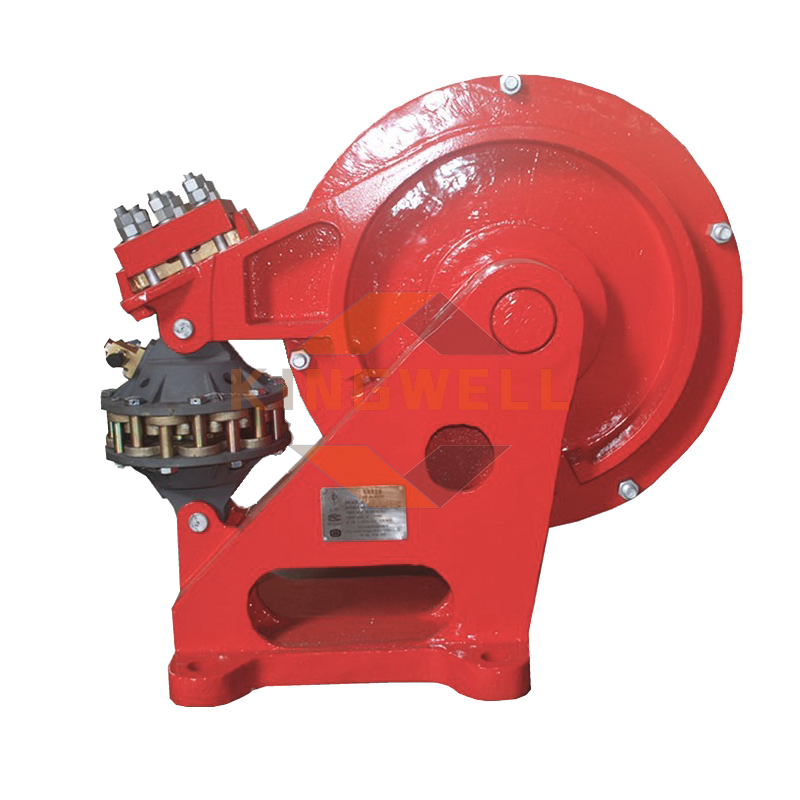

Crown blocks of drilling rig are available with lifting capacity from 30 to 675 tons. The crown block is lifted onto the tower in assembled form with the auxiliary and tartar blocks installed. Auxiliary blocks for the cable coming from the auxiliary winch or other special devices are suspended from the crown block frame. The pulley sections consist of axles mounted on bearings, clamped on the axle, locked with a screw, followed by installation of cotter pins in the groove of the nut. The pulley sections are covered with casings on top. The top end of the guide for the top drive system is also attached to the crown block frame.

Technical Parameters for Drilling Crown Block

| Model | Ropes | Wire rope dia. in | Load lbf | Main pulley dia in | Fast line dia. in | Bailing wheel dia. in | Overall dimension ft | Dead weight lbs |

| TC60 | 3x2 | 7/8 | 134885 | 19.68 | 19.68 | 5.37x4.36x4.89 | 1305 | |

| TC70 | 4x3 | 7/8 | 157366 | 24.02 | 24.02 | 4.86x2.05x2.07 | 1598 | |

| TC90 | 4x3 | 1 | 202328 | 24.02 | 24.02 | 4.46x3.28x4.10 | 1764 | |

| TC135 | 4x3 | 1 | 303492 | 29.92 | 36.02 | 6.09x4.95x4.27 | 2866 | |

| TC158 | 5x4 | 1 1 1/8 | 355198 | 29.92 | 36.02 | 19.68 | 7.64x4.69x4.82 | 3263 |

| TC158 | 6x5 | 1 1 1/8 | 355198 | 29.92 | 36.02 | 19.68 | 7.64x5.38x4.82 | 3472 |

| TC160 | 4x3 | 1 1/8 | 359694 | 36.02 | 36.02 | 19.68 | 7.23x3.23x3.41 | 4393 |

| TC180 | 6x5 | 1 1/4 | 404656 | 36.02 | 36.02 | 8.14x2.70x3.18 | 4574 | |

| TC225 | 6x5 | 1 1/4 | 505820 | 36.02 | 36.02 | 19.68 | 6.56x4.59x4.43 | 5158 |

| TC315 | 7x6 | 1 3/8 | 708148 | 50 | 60 | 30 | 12.84x9.67x9.24 | 19294 |

| TC450 | 7x6 | 1 1/2 | 1011640 | 60 | 60 | 29.92 | 11.38x10.06x9.73 | 21459 |

Technical Features for Drilling Crown Block

- The crown block will be manufactured in accordance with API Spec 4F and 8C.

- Each bearing of the crown block has an individual lubrication channel.

- The crown block frame is made of high-strength steel materials.

- Bearings and pulleys on the crown block are possibly interchangeable within the limits corresponding to the traveling block.

- Crown block grooves are filled for increased service life

- Rope stops are installed to prevent ropes from falling out of the groove.

- The crown block is equipped with wooden buffer blocks and fixing mesh.

- The crown block is equipped with tartar rope crown block pulleys and auxiliary pulleys.

Online consultation

Quick access to Technical Support and Detailed Quotations

Please fill out the form below so that we can quickly answer your questions and provide you with our high-quality technical support. You can also contact us through email, and our team will provide you with excellent service.

CONTACT US

-

This email address is being protected from spambots. You need JavaScript enabled to view it. -

+86 315 2031752