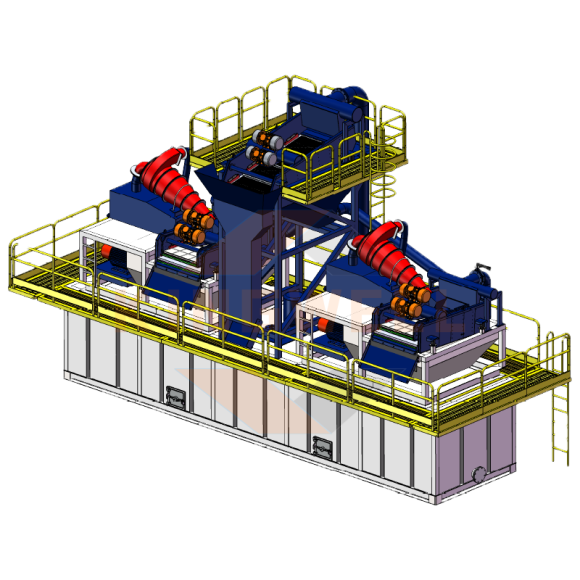

During the TBM and Pipe Jacking construction, many slurries contain sand and stones will be produced. To protect the environment and save water, it is necessary to separate the TBM slurry. KINGWELL can provides the TBM Slurry Separation Plant, which includes: shale shaker, desander, desilter, bottom drying shaker, feed pump and mud tank etc.

TBM and Pipe Jacking are often used in urban construction, which usually requires small working area and high treatment efficiency. KINGWELL TBM Slurry Separation Plant is specially designed to meet the above demands with a very compact foundation by optimal designing this treating system at different height levels. To meet the diversified operation requirements, KINGWELL TBM Slurry Separation Plant can be assembled by multiple modular units to achieve both small flow rate and large flow rate slurry treating

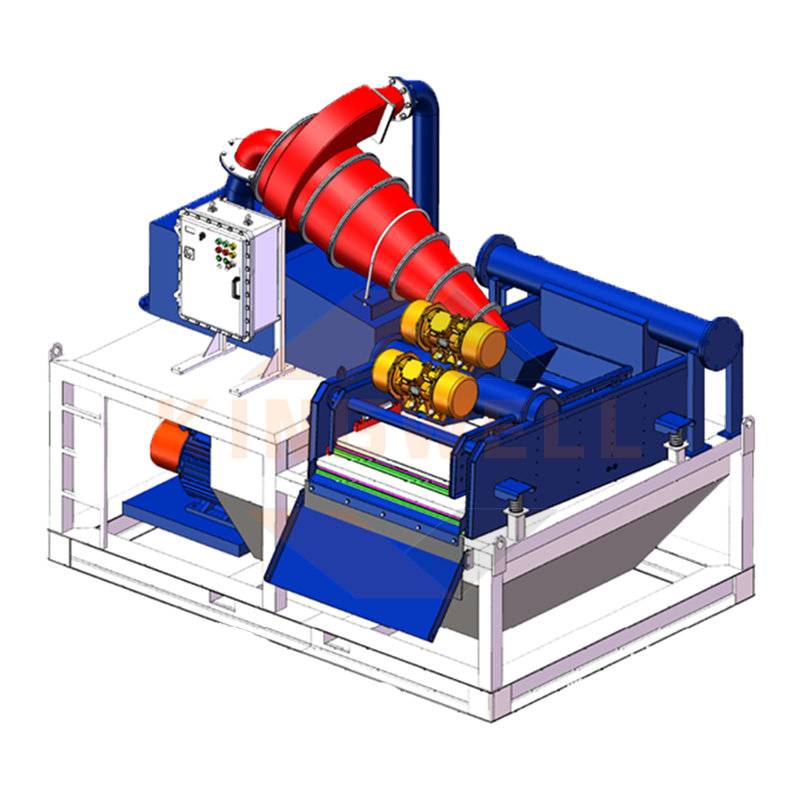

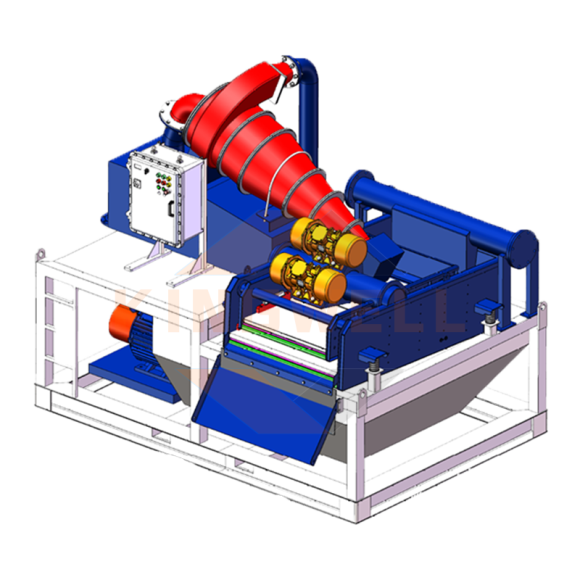

KINGWELL Desanding Plant can used for the small TBM and Pipe Jacking construction, and we also the big size for TBM and Pipe Jacking construction.

| Model | Capacity | Screen area | Cleaning stage | Total power | Total weight | Transport dimensions,mm |

|---|---|---|---|---|---|---|

| KWMS200 | 50m3/h(200GPM) | 2.2m2 | 2 | 14kw | 2.7T | L3103*W1896*H2637 |

| KWMS500 | 120m3/h(500GPM) | 2.2m2 | 2 | 39kw | 2.9T | L3506*W1896*H2441 |

| KWMS1000 | 240m3/h(1000GPM) | 3.98m2 | 2 | 59kw | 3.7T | L4176*W2162*H3796 |