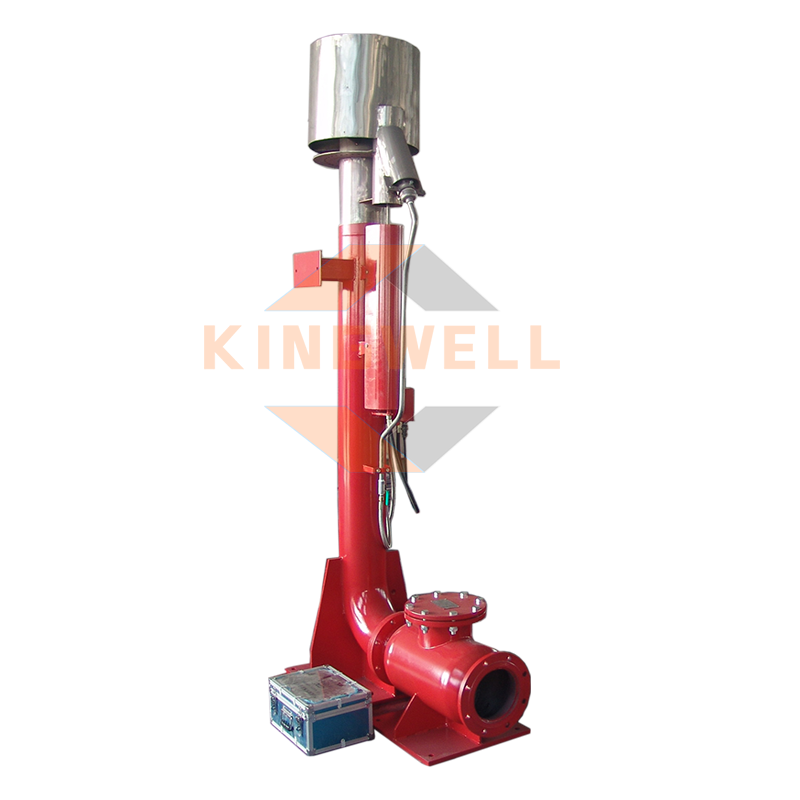

Disc Stack Separator

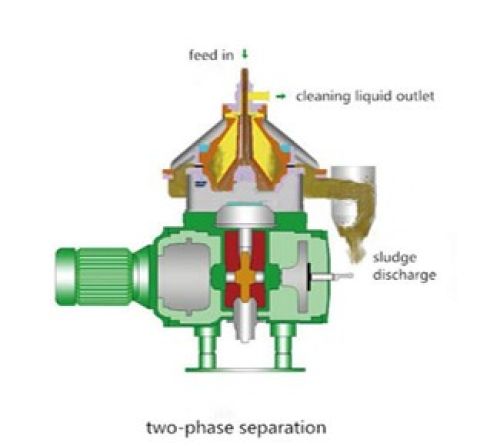

Disc Stack Separator is also called Disc Stack Centrifuge, which belongs to a type of vertical centrifuge. The disc separator is driven by a motor and rotates at high speed. The main functions of the disc stack centrifuge are purification, concentration and clarification. KINGWELL Disc Stack Separator can reach up to 12000G, with higher rotation speed and high separation factor, they handle liquids optimally.

The disc stack separator is specially used for the two-phase separation (2 phase Disc Stack Separator) and three phase separation (3 phase Disc Stack Separator). Typically, the disc separator is used in any industry: food industry, beverage industry, pharmaceuticals, shipbuilding, oil and gas industry and many others.

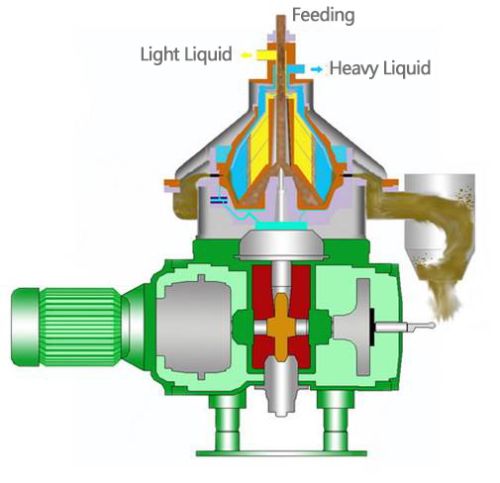

Working principle of Disc Stack Separator

The materials are transmitted to the heart parts of disc stack separator, the inside drum. Under the action of strong centrifugal force, the materials pass through the interval of a group of disc pieces bundles, and then, regarding the neutral hole of the disk pieces as the interface, the liquid with higher density moves outward the neutral hole along the disk pieces, among which, the heavy residues accumulate in the sediment area, and the heavy phase flows to the large centripetal pump. The liquid with lower density (Light phase) moves inward and upward along the disk pieces wall and gathers in the small centripetal pump. The heavy phase and light phase output by the large centripetal pump and small centripetal pump respectively.

1. Disc Stack Separator for Pharmaceutical biotechnology

Mechanical separation is an important part of the numerous processes in biological pharmacy. The quality of separation is decisive to the quality of final products, economic efficiency of processes and environmental coexistence. Disc Stack Separators are widely used for the separation of microbes and their debris such as treatment of vaccine, amino acid, enzyme, starter culture and other fermented products, because they are designed and manufactured with the aim to separate and purify cell protein, to extract materials during the production of antibiotics, alkaloids and hormones, and to separate animal plasma.

2. Disc Stack Separator for Vegetable Oil & Animal Oil Separation

Enough oil should be ensured in human’s dietary, so the oil quality affects the human health directly. KINGWELL Disc Stack Separator can suitable for a variety of oils and fats and provide customized solutions to achieve optimal oil and maximized production capacity. Disc Stack Separators are widely used for the separation of vegetable oil & animal oil.

3. Disc Stack Separator for Separation of the Dairy, Beverage, Beer production

Disc Stack Separators are widely used for diary clarifying, separation of milk and cream, separation of syrup and vegetable juice, separation of tea drinks, coffee, beer and other industries. The disc stack separator has the special design for the centripetal pump and inlet/outlet port will create a soft separation environment for the materials, to ensure the active ingredient in the materials is not destroyed and made the nutritional value and freshness as well as good. KINGWELL Disc Stack Separator can separate the extreme tiny(as less than 1 μm) solid particles which dispersed in suspensions from the liquid out.

4. Disc Stack Separator for Marine Fuel & Mineral Oil Separation

The Disc Stack Separator is mainly used for cleaning up the moisture and mechanical impurity in the fuel (light diesel oil, heavy diesel oil, fuel oil etc.) and lubricating oil of ships and diesel engine, which is good to reduce the abrasion and prolong its service life. The heave diesel oil is separated by dis separator can replace the light diesel oil for using, so that can reduce the cost of production.

5. Disc Stack Separator for Biodiesel Oil Production

The Disc Stack Separator is mainly used for separation of methyl, ester, glycerin, catalyst, de-soap, methanol, and methyl washing, and extraction of fatty acids, and glycerol desalination.

6. Disc Stack Separator for Chemical Production

The Disc Stack Separator is mainly used for production of lubricating oil additives, glue liquid, PVC, cellulose and derivatives, inks and dyes, phosphoric acid, herbicides, latex, boiler ask, catalyst, et.

7. Disc Stack Separator for Vegetable Extraction

KINGWELL is able to provide the full set separation solution with combination of disc stack separator and decanter centrifuge, which can achieve more efficient separation goals for users to separate different materials

Online consultation

Quick access to Technical Support and Detailed Quotations

CONTACT US

-

This email address is being protected from spambots. You need JavaScript enabled to view it. -

+86 315 2031752