Mud Cooling System

PRODUCTS

- Oil Drilling rig & Equipment

- Solids Control

- Shale Shaker

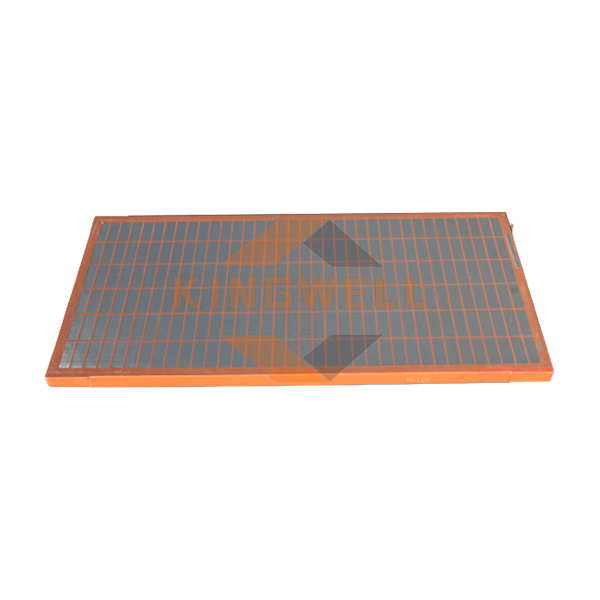

- API Shaker screens

- Decanter centrifuge

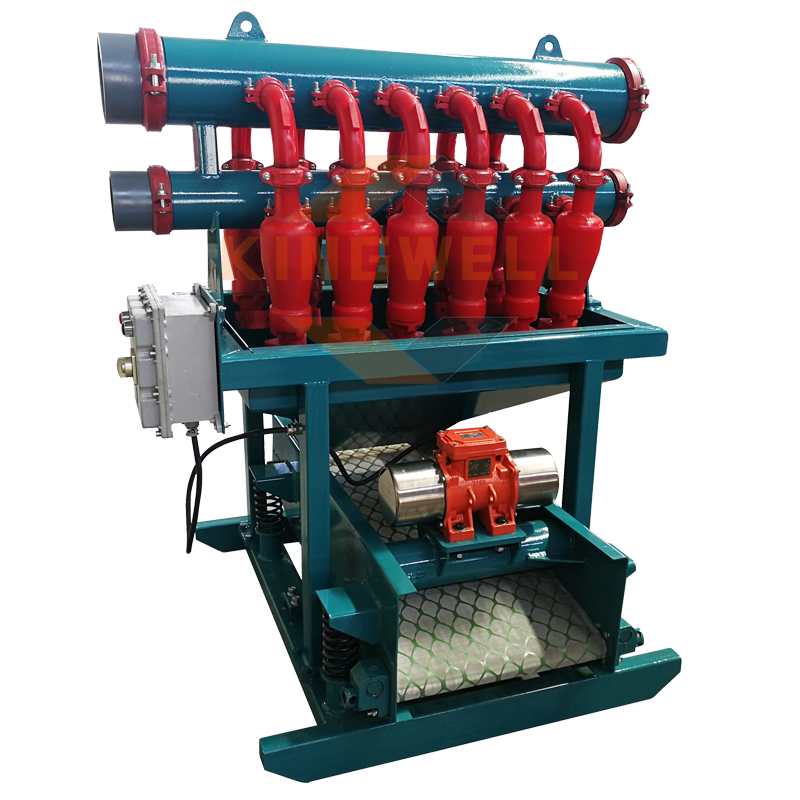

- Mud Cleaner

- Desander

- Desilter

- Centrifugal Degasser

- Vacuum Degasser

- Mud Agitator

- Mud Hopper

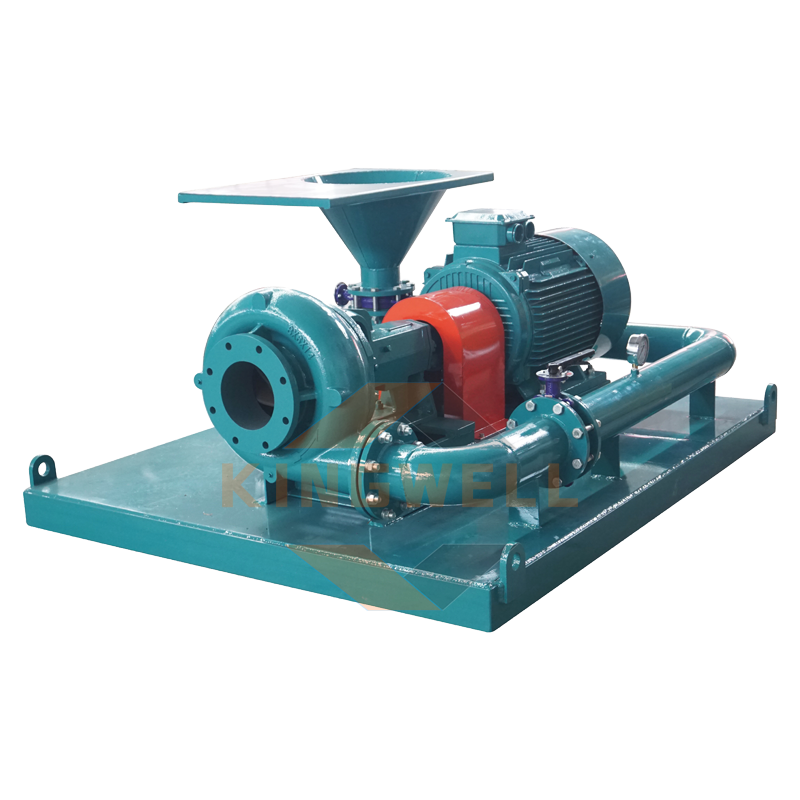

- Jet Mud Mixer

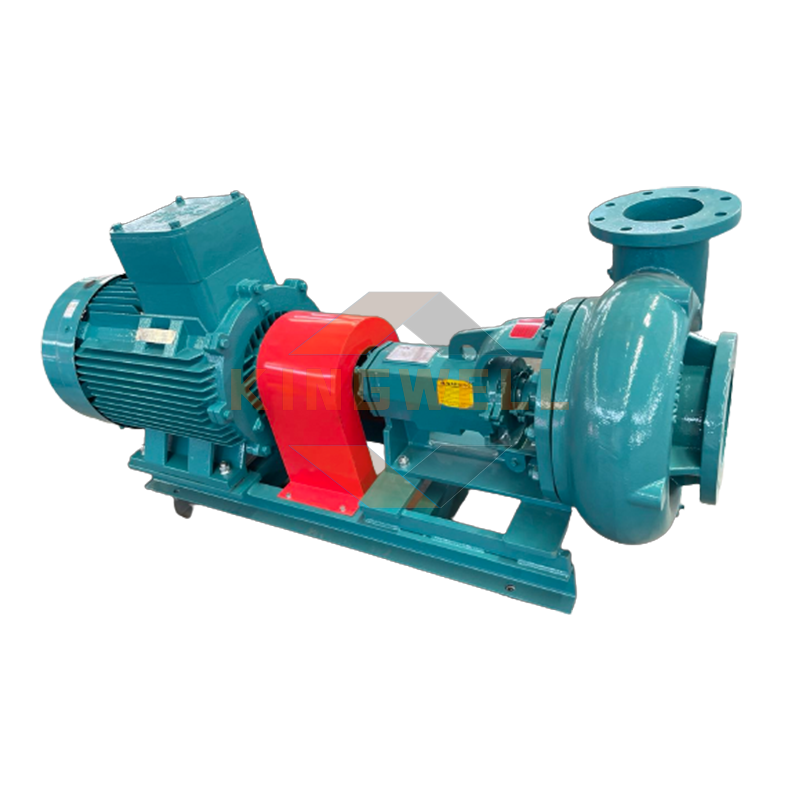

- Centrifugal Pump

- Screw Conveyer

- Screw Pump

- Submersible Slurry Pump

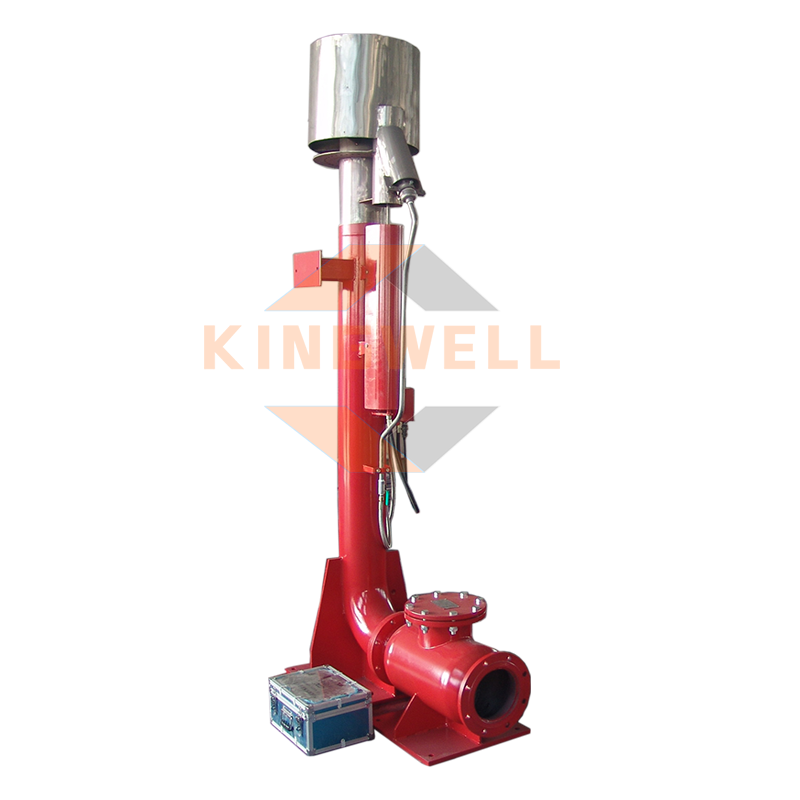

- Flare Ignition Device

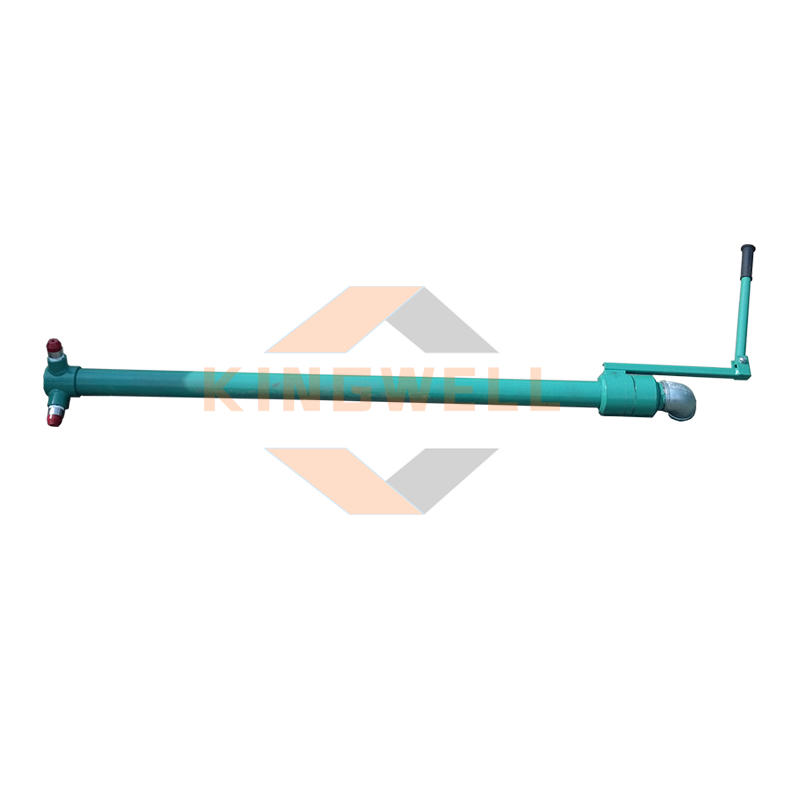

- Mud Gun

- Mud Solids Control System

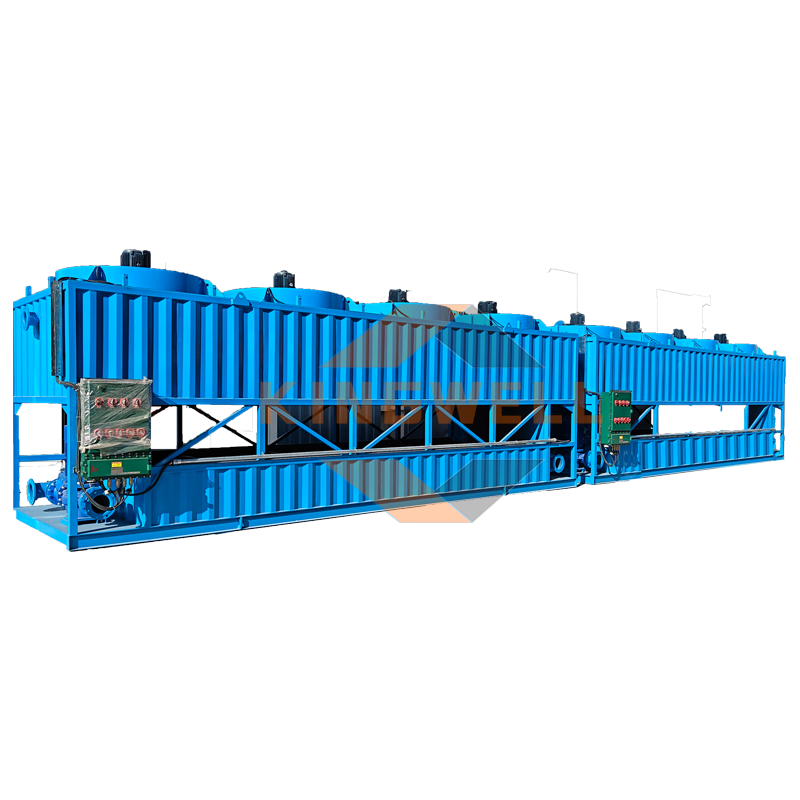

- Mud Cooling System

- Mud Tanks

- Drilling Waste Management

- Separation Technology

- Packaged Mud Recycling Systems

Mud Cooling System Application

During the oil and gas drilling, a large amount of heat is generated as the drilling tool cuts the rock, and the friction between the drilling tool and the borehole wall generates a large amount of heat. As the drilling depth increases, the temperature at the bottom gradually increases, and the temperature of the drilling fluid also increases. If the mud temperature is too high, it will cause a certain corrosion of drilling tools and transport equipment, shortening the service life of drilling tools. This will also affect the composition and function of the solution. In severe cases, lead to the destruction of the drilling fluid's ability and it is impossible to protect the well walls.

Therefore, when drilling, using an oil- and water-based drilling fluid cooling system can reduce the bottomhole temperature, increase the stability of drilling tools and extend the service life of drilling tools, and shorten the well construction cycle.

Working Technology of Mud Cooling System

The mud cooling system mainly includes: feed pump, plate heat exchanger, cooling tower and water storage tank. The high-temperature mud is supplied to the plate heat exchanger by feed pump for heat exchange. After heat exchange, the drilling mud output is discharged through the outlet pipeline, the low-temperature water in the water storage tank is sent to the plate heat exchanger for heat exchange through the pump, and the high-temperature water is discharged into the cooling tower, cooled by forced cooling fan in the cooling tower and finally flows into the water storage tank. This cycle is repeated to cool the drilling fluid.

Technical Specifications of Mud Cooling System

| Model | KWMCS240 |

|---|---|

| General power | 104.5kW |

| Capacity | 240m³/h |

| Mud temperature in inlet | 45-90℃ |

| Mud temperature in outlet | 30-38℃ |

| High temperature mud inlet | DN200 PN10 |

| Low temperature mud inlet | DN200 PN10 |

| High temperature water inlet | DN200 PN10 |

| Low temperature water inlet | DN200 PN10 |

Online consultation

Quick access to Technical Support and Detailed Quotations

CONTACT US

-

This email address is being protected from spambots. You need JavaScript enabled to view it. -

+86 315 2031752