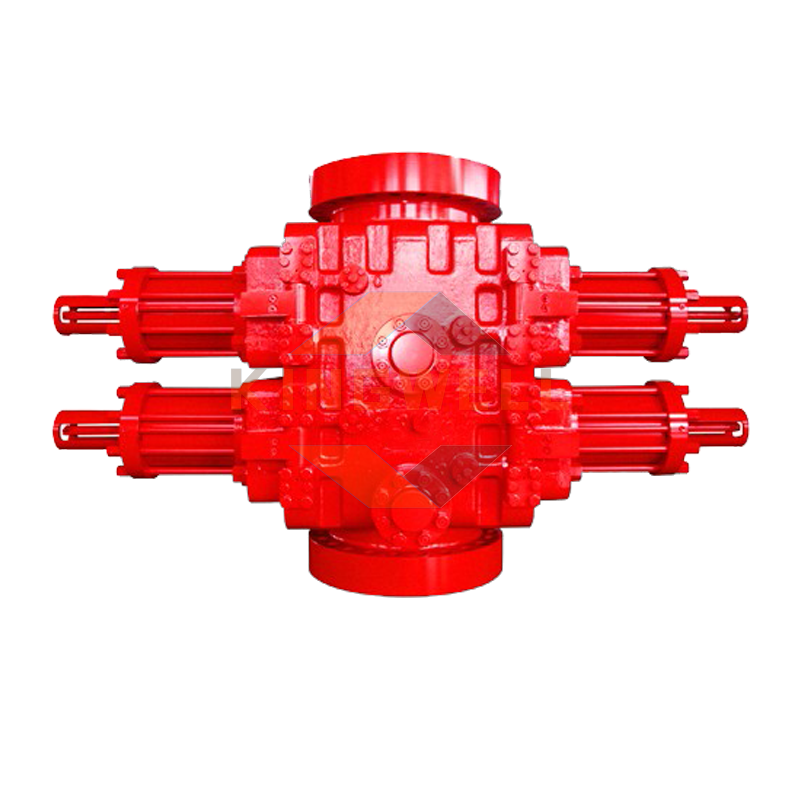

Annular BOP

Annular BOP (annular blowout preventer) is designed to seal the wellhead with or without a drill string. The annular blowout preventer is the most important component on any rig. The annular BOP provides increased safety during oil well operation. The purpose of annular BOP is to protect the drilling rig from possible explosion and fire.

Annular blowout preventers are capable of sealing multiple sizes of drill pipe/drill collars, work string, wireline, tubing, etc. Some models can use wellbore pressure to provide additional sealing ability. The annular BOP consists of a body, a cover, a piston and a rubber sealing element.

The main element of the annular BOP is a durable elastic rubber seal in the shape of a ring, housed in a steel casing. Under the sealing ring there is a conical piston. When the annular blowout preventer is closed using hydraulic fluid, a working pressure is created in the piston cavity, which is transmitted to the sealing ring. In terms of sealing, the annular blowout preventer has 2 types: the spherical rubber and the conical rubber.

The spherical rubber annular blowout preventer has the characteristics of simple structure, convenient disassembly and firm sealing.

The conical rubber annular blowout preventer has only the piston and the conical rubber core as moving parts, which effectively reduces the wear area of the cone core and prolongs the service life of the rubber core.

1. Annular BOP with spherical rubber

Technical Parameters for Annular BOP with spherical rubber

| Type | Bore size | Rated operating pressure | Volume to open chamber | Volume to close chamber | Closure range | Dimensions | Weight | |

| 7 1/16'' 3000PSI | FH18-21 | 179.4mm 7 1/16'' | 21Mpa (3000PSI) | 15L | 21L | 0-179.4mm 0-7 1/16'' | 745x769mm | 1432kg |

| 7 1/16'' 5000PSI | FH18-35 | 179.4mm 7 1/16'' | 35Mpa (5000PSI) | 15L | 21L | 0-179.4mm 0-7 1/16'' | 745x797mm | 1520kg |

| 9'' 3000PSI | FH23-21 | 228.6mm 9'' | 21Mpa (3000PSI) | 27L | 39L | 0-228.6mm 0-9'' | 908x838mm | 2440kg |

| 9'' 5000PSI | FH23-35 | 228.6mm 9'' | 35Mpa (5000PSI) | 33L | 42L | 0-228.6mm 0-9'' | 1016x924mm | 3050kg |

| 11'' 2000PSI | FH28-14 | 279.4mm 11'' | 14Mpa (2000PSI) | 33L | 46L | 0-279.4mm 0-11'' | 1013x855mm | 3547kg |

| 11'' 3000PSI | FH28-21 | 279.4mm 11'' | 21Mpa (3000PSI) | 33L | 46L | 0-279.4mm 0-11'' | 1013x873mm | 3400kg |

| 11'' 5000PSI | FH28-35 | 279.4mm 11'' | 35Mpa (5000PSI) | 56L | 72L | 0-279.4mm 0-11'' | 1146x1104mm | 4643kg |

| 13 5/8'' 3000PSI | FH35-21 | 341.6mm 13 5/8'' | 21Mpa (3000PSI) | 72L | 98L | 0-346.1mm 0-13 5/8'' | 1271x1176mm | 5700kg |

| 13 5/8'' 5000PSI | FH35-35 | 341.6mm 13 5/8'' | 35Mpa (5000PSI) | 72L | 98L | 0-346.1mm 0-13 5/8'' | 1271x1176mm | 6448kg |

| 18 3/4'' 5000PSI | FH48-35 | 476.3mm 18 3/4'' | 35Mpa (5000PSI) | 172L | 220L | 0-476.3mm 0-18 3/4'' | 1780x1710mm | 16320kg |

| 20 3/4'' 3000PSI | FH53-21 | 527mm 20 3/4' | 21Mpa (3000PSI) | 110L | 173L | 0-527mm 0-20 3/4'' | 1375x1293mm | 7133kg |

| 21 1/4'' 5000PSI | FH54-35 | 539.7mm 21 1/4'' | 35Mpa (5000PSI) | 171L | 227L | 0-539.7mm 0-21 1/4'' | 1938x1742mm | 20220kg |

Technical features for Annular BOP with the spherical rubber core

- Design and manufacture of annular BOP according to API Spec 16A.

- Corrosion-resistant working bodies inside the annular BOP that come into contact with aggressive media (hydrogen sulfide) are made in accordance with the requirements of NACE MR-175.

- Annular BOP with the spherical rubber core provides increased safety at pressures up to 70 MPa, flexibility of technological operations, and does not impose special requirements on maintenance;

- The presence of only 2 moving parts (piston and seal) gives the product reliability, efficiency and reduces operating costs;

- The simplicity of the design makes it easy to replace all seals and main parts if necessary;

- A built-in heating chamber for the working area of the seal allows you to operate the preventer in cold weather;

2. Annular BOP with conical rubuer

Technical Parameters for Annular BOP with conical rubber

| Type | Bore size | Rated operating pressure | Volume to open chamber | Volume to close chamber | Closure range | Dimensions | Weight | |

| 11'' 10000PSI | FHZ28-70 | 279.4mm 11'' | 70Mpa (10000PSI) | 66L | 67L | 0-279.4mm 0-11'' | 1687x1653mm | 12290kg |

| 11'' 15000PSI | FHZ28-105 | 279.4mm 11'' | 105Mpa (15000PSI) | 120L | 121L | 0-279.4mm 0-11'' | 1650x1959mm | 17640kg |

| 13 5/8'' 5000PSI | FHZ35-35 | 341.6mm 13 5/8'' | 35Mpa (5000PSI) | 54L | 68L | 0-346.1mm 0-13 5/8''' | 1510x1434mm | 6917kg |

| 13 5/8'' 10000PSI | FHZ35-70 | 341.6mm 13 5/8'' | 70Mpa (10000PSI) | 117L | 116L | 0-346.1mm 0-13 5/8''' | 1780x1787mm | 15190kg |

| 16 3/4'' 3000PSI | FHZ43-21 | 425.5mm 16 3/4'' | 21Mpa (3000PSI) | 84L | 118L | 0-425.5mm 0-16 3/4'' | 1598x1553mm | 7258kg |

| 16 3/4'' 5000PSI | FHZ43-35 | 425.5mm 16 3/4'' | 35Mpa (5000PSI) | 78L | 112L | 0-425.5mm 0-16 3/4'' | 1728x1630mm | 10030kg |

| 20 1/4'' 2000PSI | FHZ54-14 | 539.7mm 20 1/4'' | 14Mpa (2000PSI) | 78.5L | 141.6L | 0-539.7mm 0-20 1/4'' | 1762x1501mm | 7696kg |

Technical features for Annular BOP with conical rubbere

- Design and manufacture of annular BOP according to API Spec 16A.

- Corrosion-resistant working bodies inside the annular BOP that come into contact with aggressive media (hydrogen sulfide) are made in accordance with the requirements of NACE MR-175.

- Use a tapered sealing assembly and the annular BOP head and housing are connected by latches.

- The annular BOP Dynamic Seal has a lip-shaped O-ring to minimize wear on the o-ring and ensure a reliable seal.

- Only the piston and sealing assembly are moving parts, which effectively reduces the wear area and shortens maintenance and repair time.

- The pressure of the well facilitates sealing.

Online consultation

Quick access to Technical Support and Detailed Quotations

CONTACT US

-

This email address is being protected from spambots. You need JavaScript enabled to view it. -

+86 315 2031752