Jet Mud Mixer

PRODUCTS

- Oil Drilling rig & Equipment

- Solids Control

- Shale Shaker

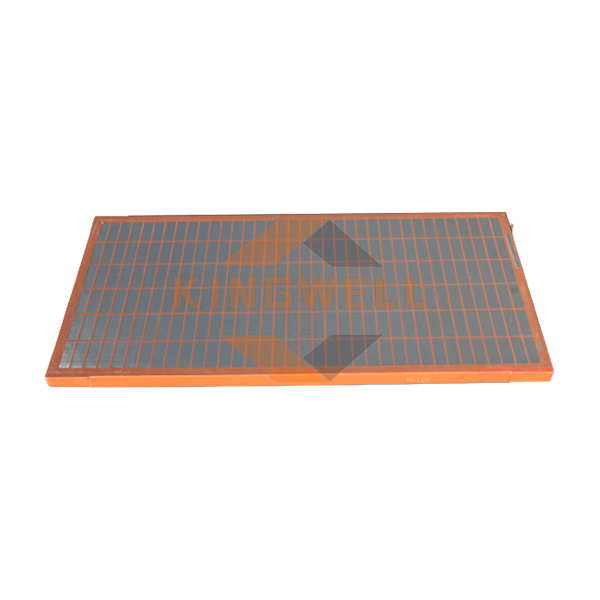

- API Shaker screens

- Decanter centrifuge

- Mud Cleaner

- Desander

- Desilter

- Centrifugal Degasser

- Vacuum Degasser

- Mud Agitator

- Mud Hopper

- Jet Mud Mixer

- Centrifugal Pump

- Screw Conveyer

- Screw Pump

- Submersible Slurry Pump

- Flare Ignition Device

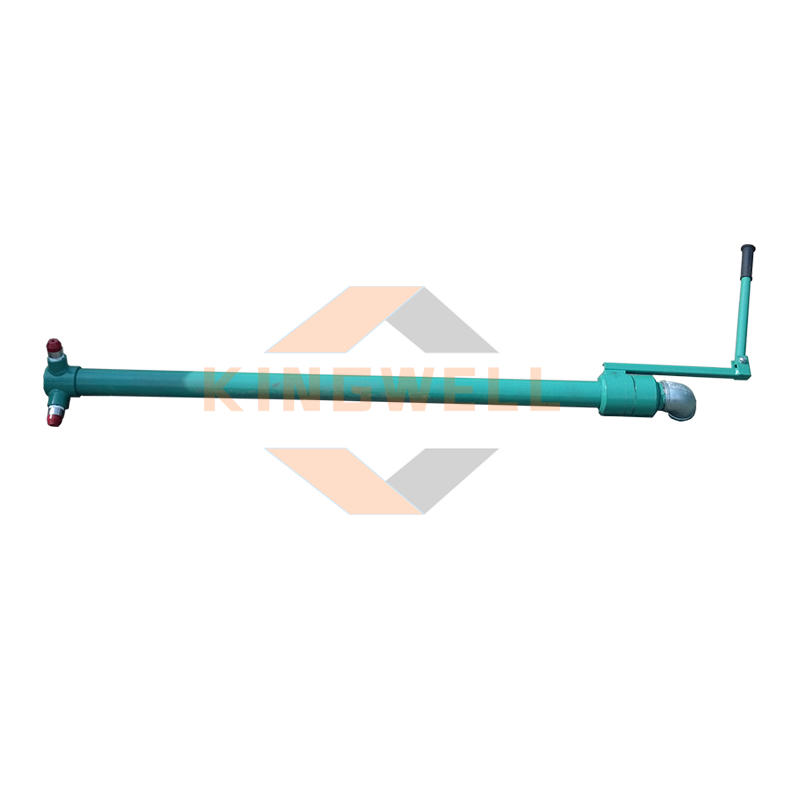

- Mud Gun

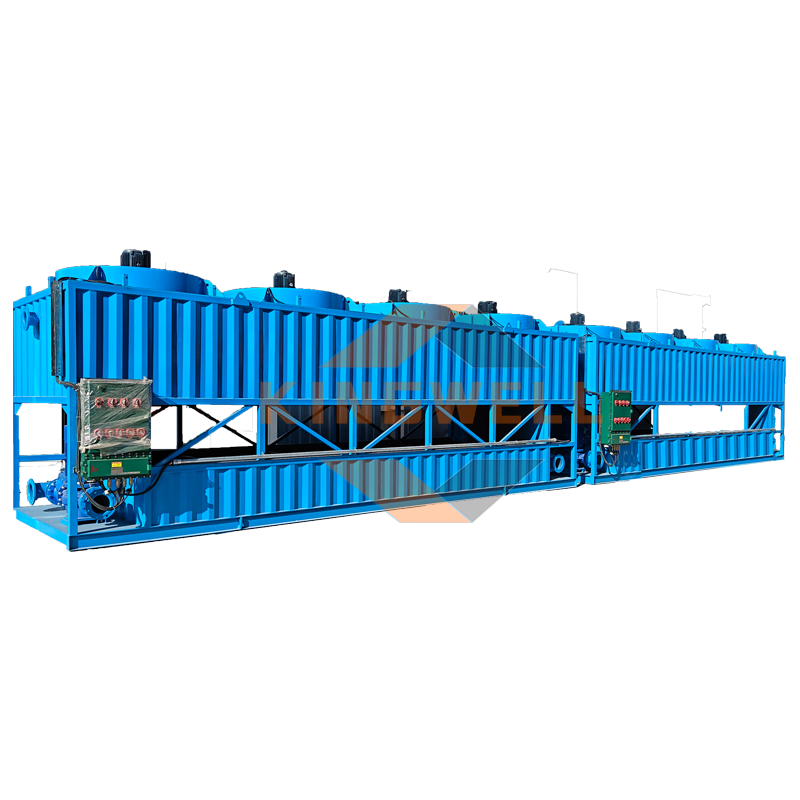

- Mud Solids Control System

- Mud Cooling System

- Mud Tanks

- Drilling Waste Management

- Separation Technology

- Packaged Mud Recycling Systems

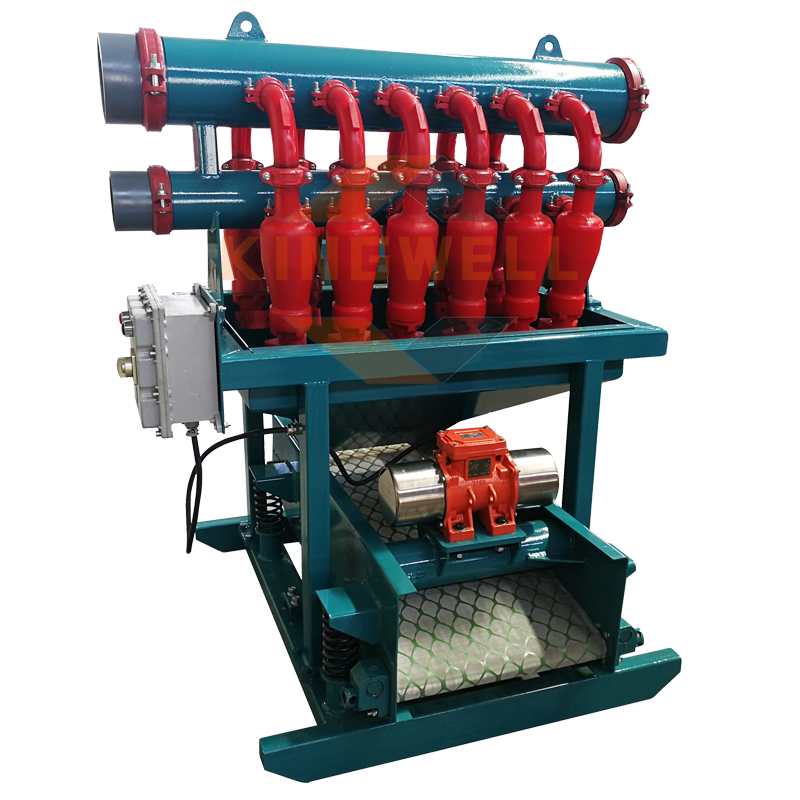

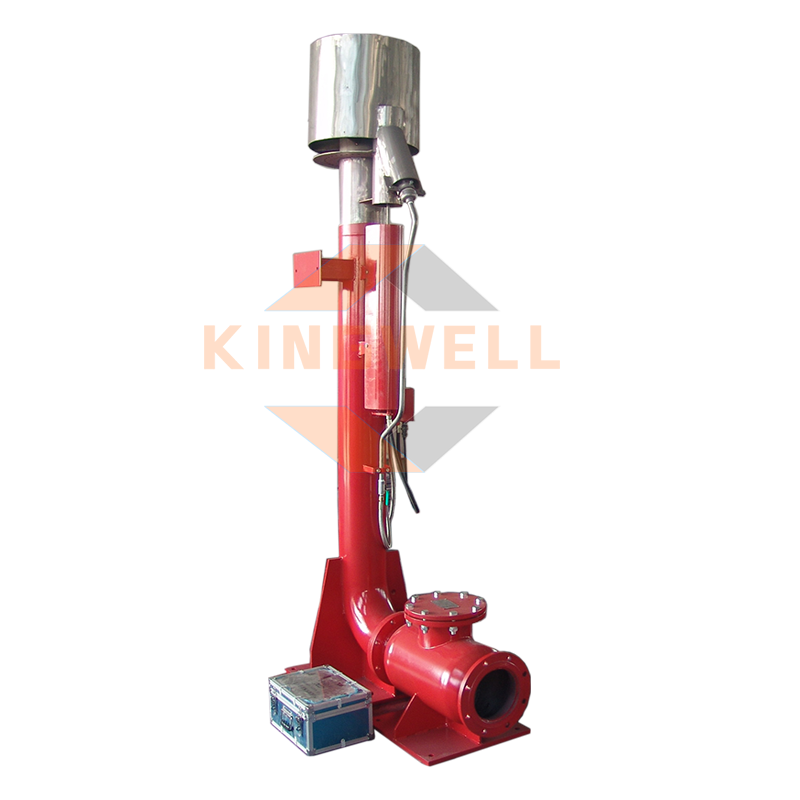

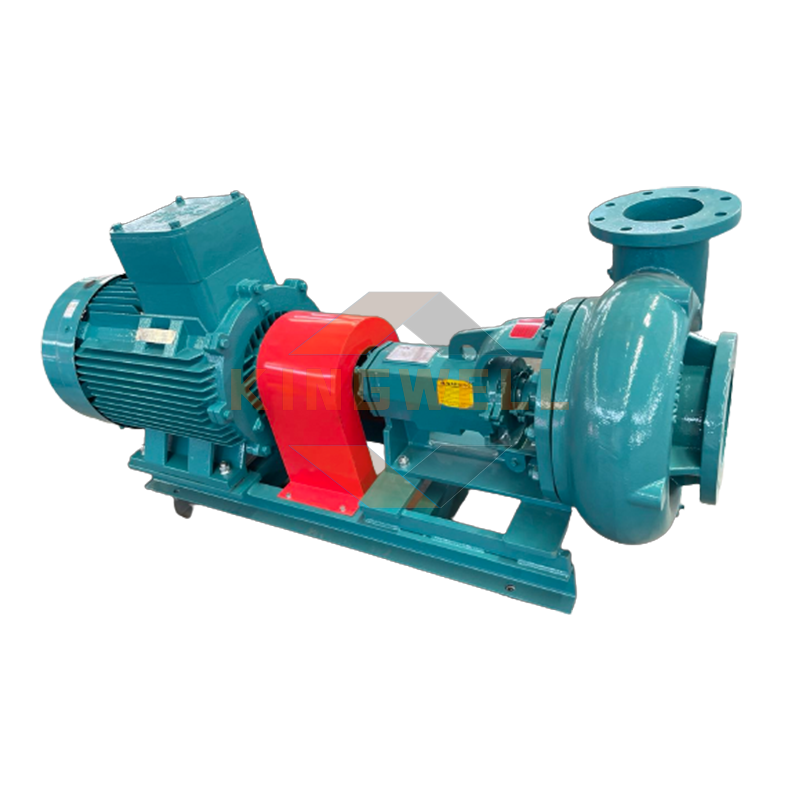

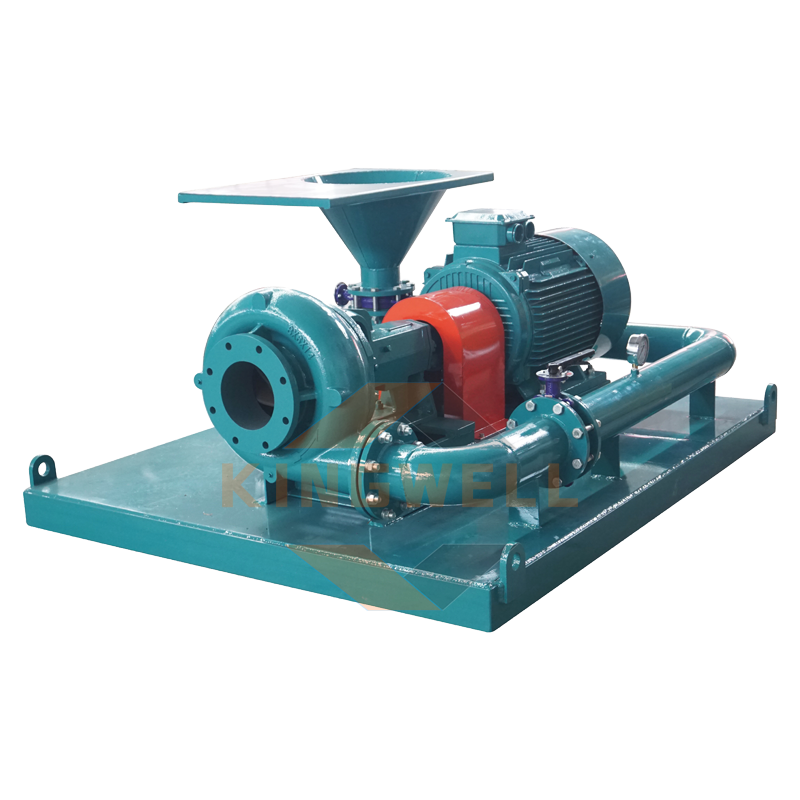

Jet mud mixer is designed for mixing barite or bentonite with drilling fluids and regulating the density and viscosity of the drilling fluid. Jet mud mixer consists of mud hopper(Verturi hopper), slurry pumps, pipeline, control panel, etc. The control panel for hydraulic mixers is not included as standard, is an additional requirement. If you need control panel for jet mud mixer, we can supply you jet mud mixer with control panel.

The single jet mud mixer consists of one set of centrifugal pump, one set of mud hopper and one set of control panel. The double jet mud mixer is composed of double pumps and double mud hoppers connected by manifold valves and hoses to achieve high mixing performance.

KINGWELL Jet mud mixer can be used to work for oil & gas drilling mud system, HDD mud cleaning system, TBM mud purification system, Pipe jacking mud plant etc.

Technical Specifications of Jet Mud Mixer

| Model | Capacity, m3/h | Lift, m | Power, kW | Inlet, inches | Outlet, inches | Weight, kg | Dimensions LxWxH, mm |

|---|---|---|---|---|---|---|---|

| KWSLH750 | 255 | 32 | 75 | 8 | 6 | 1785 | 2200x1840x1150 |

| KWSLH550 | 250 | 24 | 55 | 8 | 6 | 1675 | 2200x1840x1100 |

| KWSLH450 | 220 | 23 | 45 | 6 | 5 | 1475 | 2200x1840x1135 |

| KWSLH370 | 190 | 24 | 37 | 6 | 5 | 1460 | 2200x1840x1135 |

| KWSLH300 | 110 | 32 | 30 | 5 | 4 | 1380 | 2200x1840x1100 |

| KWSLH220 | 105 | 27 | 22 | 5 | 4 | 1167 | 1850x1540x1000 |

| KWSLH185 | 100 | 21 | 18.5 | 5 | 4 | 1147 | 1850x1540x1030 |

| KWSLH150 | 80 | 21 | 15 | 4 | 3 | 970 | 1850x1540x1030 |

| KWSLH110 | 50 | 25 | 11 | 3 | 2 | 950 | 1850x1540x1030 |

Technical Features of Jet Mud mixer

Jet Mud mixer has wide working pressure range: 0.25~0.4MPa

- Available in both explosion-proof and non-explosion-proof standard;

- Explosion protection is standard, can choose EXdIIBt4/IEC/ATEX.

- The centrifugal pump is interchangeable with the NOV Mission pump, which helps the customer purchase spare parts more easily.

- High precision processing pump with wear-resistant production material helps improve productivity

- High quality mechanical seal to prevent pump leakage and reduce maintenance.

- Bearings from leading manufacturers for centrifugal pumps, stable operation and long service life

- 3 layers of marine anti-corrosion paint.

- Electrical elements: SIEMENS, Schneider, ABB, CHINT, etc.

Online consultation

Quick access to Technical Support and Detailed Quotations

CONTACT US

-

This email address is being protected from spambots. You need JavaScript enabled to view it. -

+86 315 2031752