Chemical Dosing Unit

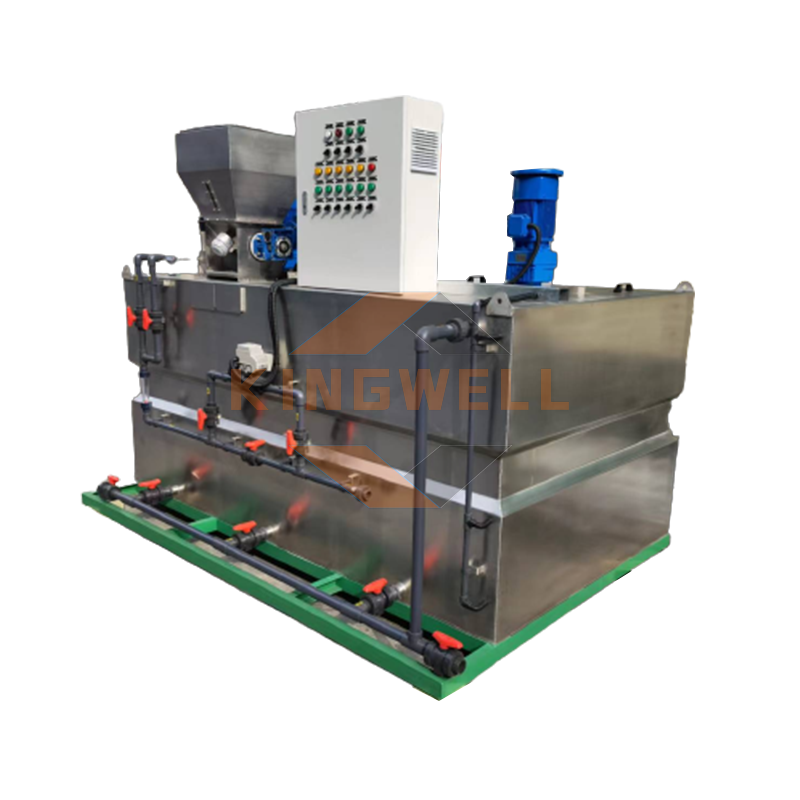

Chemical dosing unit is designed to reduce the cost of waste disposal during oil and gas drilling by processing this waste and obtaining clean process water. The recycled water can be reused to prepare drilling fluids. Oil and gas drilling typically uses chemical dosing unit to remove fine solids less than 5 microns from water-based drilling fluids with horizontal centrifuge to improve its throughput and operating efficiency. Because of its wide applicability, the dosing unit can be used with main dewatering equipment such as decanter centrifuge, screw press and filter press for preparation and dosing flocculants solvent.

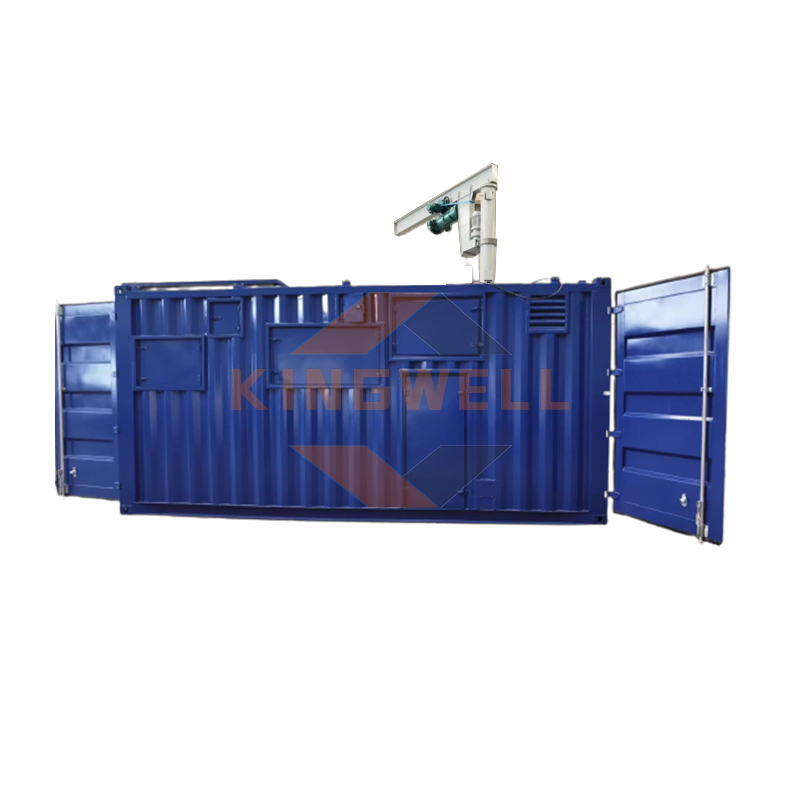

Chemical dosing unit can be installed in an insulated container to allow operation in areas with moderate cold climates. Or made according to your individual requirements.

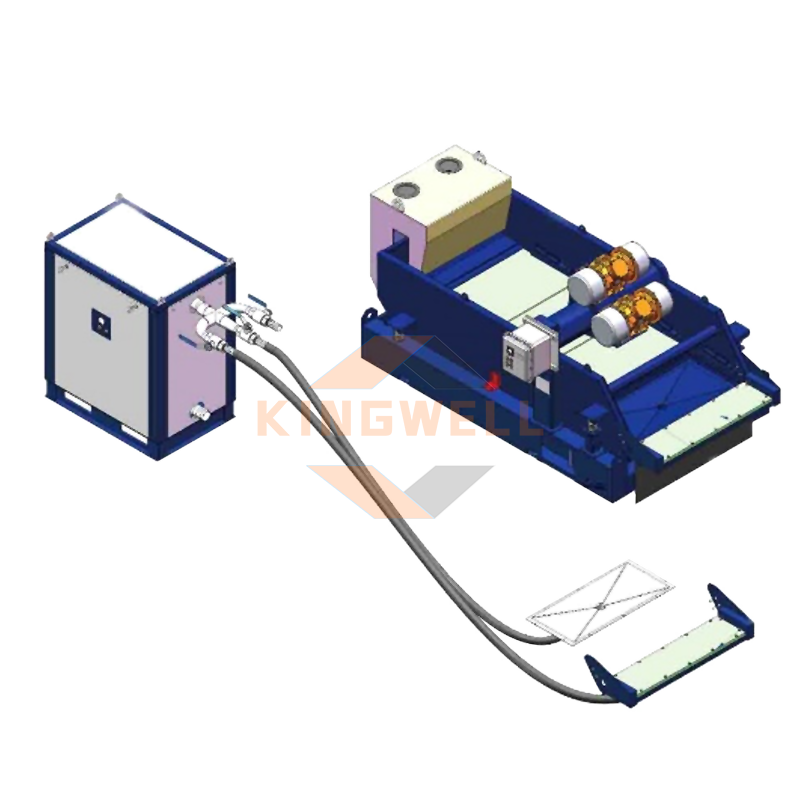

1. Automatic Chemical Dosing Unit

- High integrated all-in-one Equipment. The complete system can be controlled intelligently by PLC.

- Compact structure, easy to operate and install.

- The system will automatically shut down and issue an alarm signal if the equipment fails to work.

- Stable Performance, and Fully Automatic Control.

- All contact parts with the medium are made of engineering plastics or stainless steel.

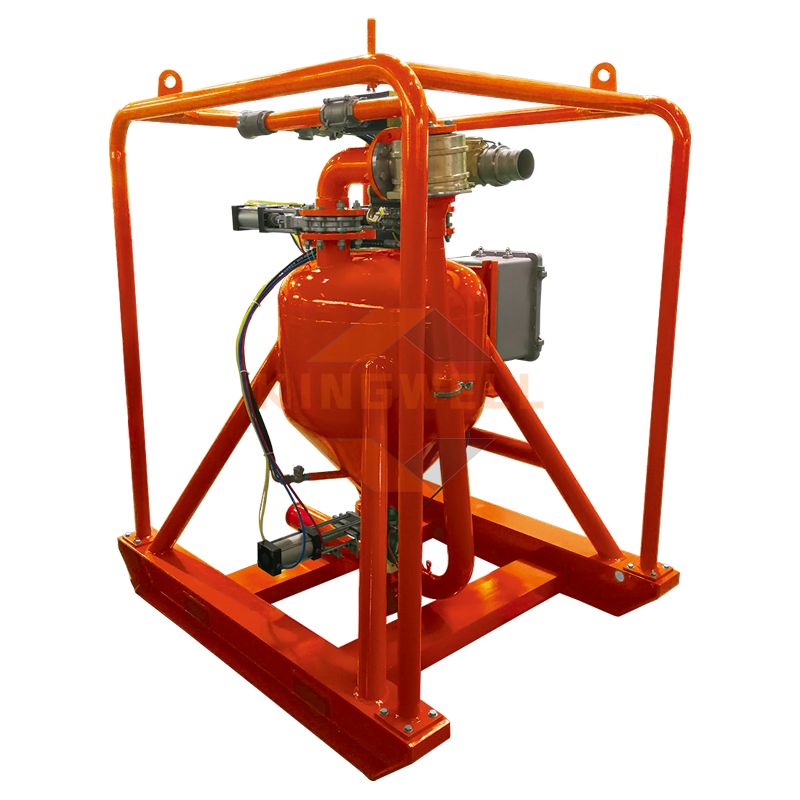

2. Manual Dosing Unit

- Stable performance, large volume of Solution Tank, and low energy consumption.

- Compact structure, beautiful appearance, and small footprint.

- Easy operation and maintenance, large dosing flow.

- PLC control, fully automatic operation, remote control is available.

3. Containerized Chemical Dosing Unit

| Chemical dosing unit | Model: KWJY2000 |

|---|---|

| Include 20ft container with decoration, include electric control system, exhaust system, lighting system. | |

|

Three Chamber automatic Dosing Unit Model: KWJY2000Z |

|

|

Single tank chemical Dosing Unit Model: KWJY2000S |

|

Online consultation

Quick access to Technical Support and Detailed Quotations

CONTACT US

-

This email address is being protected from spambots. You need JavaScript enabled to view it. -

+86 315 2031752