Decanter Centrifuge

Decanter centrifuge is a horizontal screw decanter centrifuge, which is consisting of a high-speed rotating bowl with high centrifugal G-force. Decanter centrifuge is a widely used equipment in the field of industrial solid-liquid separation. With the advanced manufacturing technology, KINGWELL decanter centrifuge can dewater, clarify and separate the suspensions with 0.002-3mm solids phase particles. According to the characteristics of different materials in different industries, KINGWELL decanter centrifuge is divided into dewatering, separation, and clarifying decanter centrifuge, which is suitable to separate various materials under different working conditions. And we also have the 3-phase decanter centrifuge for separation of liquid, liquid, and solids.

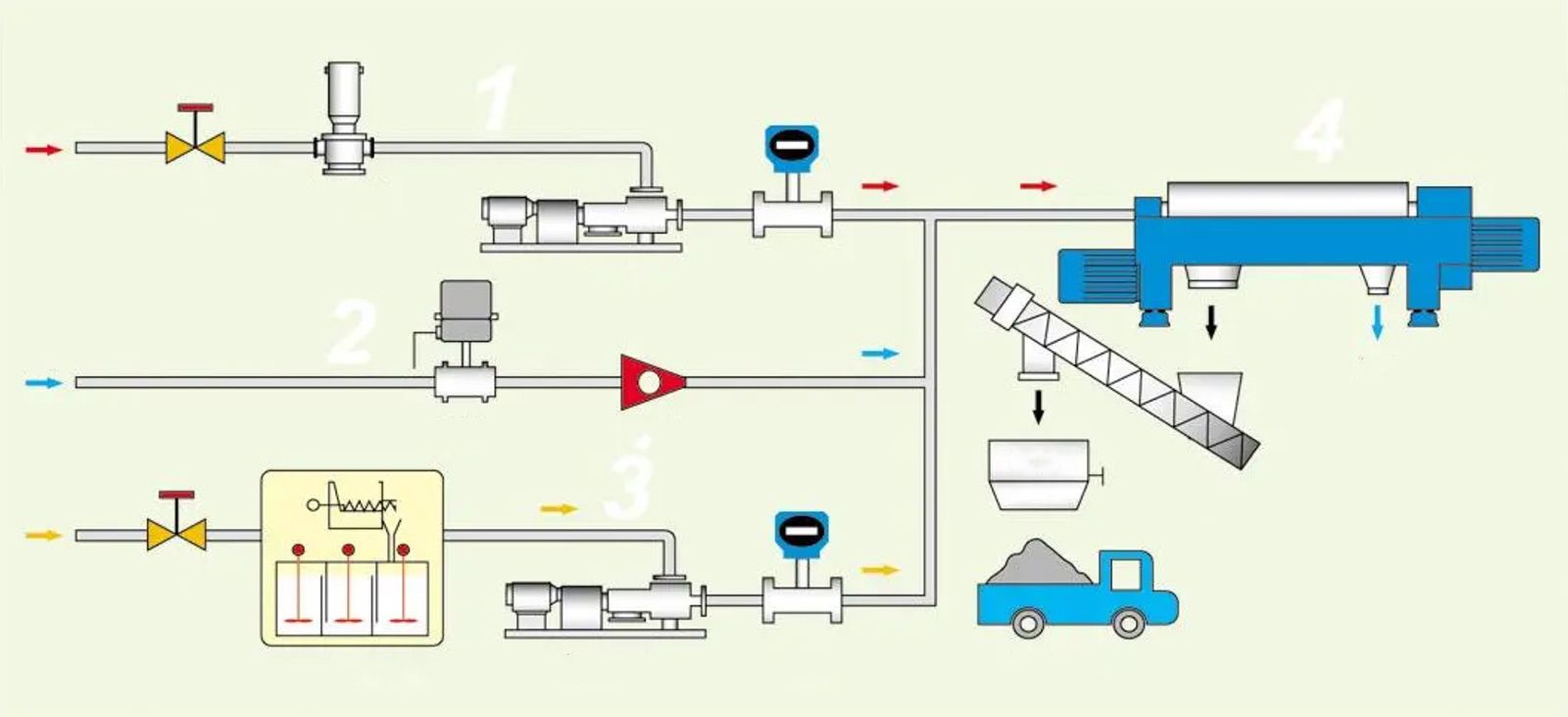

Working technology of Decanter Centrifuge

Technical Parameters for Dewatering Decanter Centrifuge

| Model | KWZ2T | KWZ3T | KWZ4T | KWZ5T | KWZ6T | KWZ7T |

|---|---|---|---|---|---|---|

| Bowl Diameter, mm | 250 | 350 | 450 | 550 | 650 | 720 |

| L/D Ration | 3-4 | 3-4 | 3-4 | 3-4 | 3-4 | 3-4 |

| Beach Angle | 8.5。 | 8.5。 | 8.5。 | 8.5。 | 8.5。 | 8.5。 |

| Max Bowl Speed, RPM | 4500 | 4000 | 3500 | 3200 | 2900 | 2400 |

| Max G Force, G | 2832 | 3133 | 4400 | 3084 | 3151 | 3085 |

| Differential speed, rpm | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 |

| Lubricant type | Grease lubrication | Oil lubrication | ||||

| Main Motor, KW | 11 | 22/30/37 | 37/45 | 55/90 | 90/110 | 110/132 |

| Back Motor, KW | 5.5 | 7.5/11 | 11/15 | 15/37 | 18.5 | 22/37 |

Technical Parameters for Separation Decanter Centrifuge

| Model | KWZ2F | KWZ3F | KWZ4F | KWZ5F | KWZ6F | KWZ7F |

| Bowl Diameter, mm | 250 | 350 | 450 | 550 | 650 | 720 |

| L/D Ration | 3-4 | 3-4 | 3-4 | 3-4 | 3-4 | 3-4 |

| Beach Angle | 15。 | 15。 | 15。 | 15。 | 15。 | 15。 |

| Max Bowl Speed, RPM | 4500 | 4000 | 3500 | 3200 | 2900 | 2400 |

| Max G Force, G | 2832 | 3133 | 4400 | 3084 | 3151 | 3085 |

| Differential speed, rpm | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 |

| Differential speed, rpm | Grease lubrication | Oil lubrication | ||||

| Lubricant type | 11 | 22 | 37/45 | 55 | 75/90/110 | 160/200 |

| Main Motor, KW | 5.5 | 7.5 | 11 | 11 | 15/18.5 | 37 |

Technical Parameters for Clarifying Decanter Centrifuge

| Model | KWZ2C | KWZ3C | KWZ4C | KWZ5C | KWZ6C | KWZ7C |

| Bowl Diameter, mm | 250 | 350 | 450 | 550 | 650 | 720 |

| L/D Ration | 3-4 | 3-4 | 3-4 | 3-4 | 3-4 | 3-4 |

| Beach Angle | 20。 | 20。 | 20。 | 20。 | 20。 | 20。 |

| Max Bowl Speed, RPM | 4500 | 4000 | 3500 | 3200 | 2900 | 2400 |

| Max G Force, G | 2832 | 3133 | 4400 | 3084 | 3151 | 3085 |

| Differential speed, rpm | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 |

| Differential speed, rpm | Grease lubrication | Oil lubrication | ||||

| Lubricant type | 11 | 22 | 37/45 | 55 | 75/90/110 | 160/200 |

| Main Motor, KW | 5.5 | 7.5 | 11 | 11 | 15/18.5 | 37 |

Technical Features for Decanter Centrifuge

- The material of decanter centrifuge bowl is made of duplex stainless steel SS2205 or SS2304, etc. using centrifugal casting and forging method to ensure high quality and long service life.

- The screw is made of duplex stainless steel SS2205 or SS2304. Heat treatment after welding to ensure high quality and long service life

- SKF or FAG brand bearings to ensure reliable performance.

- Balancing during the production to ensure the stable operation of the centrifuge under the high speed working condition

- The screw propeller is protected by replaceable wear-resistant alloy plate with long service life and easy maintenance.

- The wear-resistant sleeve of the solid discharge port is a special hard tungsten carbide sleeve, of which the wear resistance is extremely high, and not fragile

- Intelligent electrical control system: Use HMI+PLC automatic control, with frequency converters ABB, Siemens, etc.

Application for Decanter Centrifuge

- Food industry: Protein Extraction and separation, Acid Precipitation and Separation, Extraction and Recovery of Animal Protein, Starch Separation and Extraction, Juice production, Vegetable Oil Separation and Extraction, Production of Alcohol, etc.

- Environmental & wastewater industry: Municipal Wastewater Treatment, Waste Oil Recovery, Oil Sludge Treatment, Environmental Dredging Project, Sand-washing Water Treatment, Steel Plant Wastewater Treatment, Food/Kitchen Waste Treatment, etc.

- Chemistry & Pharma Industry Common Application: Pulp & Paper Industry, Polyvinyl Chloride & Polyethylene Industry, Dehydration Of Pure Alkali, White Mud, Salt Mud, Pharmaceuticals Industry, Production of Chemical Products, Biomass Separation, Collection of Algae, etc.

- Oil, gas and mining Industry: oil and gas drilling, drilling waste treatment, oil sludge treatment, Ore Treatment, Minerals Treatment, Tailings Treatment, Coal Washing, Biofuel extraction and recovery etc.

Online consultation

Quick access to Technical Support and Detailed Quotations

CONTACT US

-

This email address is being protected from spambots. You need JavaScript enabled to view it. -

+86 315 2031752